Valentine’s Day ❤️ Use code PARAMETRICLOVE for 30% OFF for Members and 15% OFF for Non-Members

Discover new skills today!

Explore classes on computational design and emerging technologies.

Learn TodayStarting at just €3.99/month

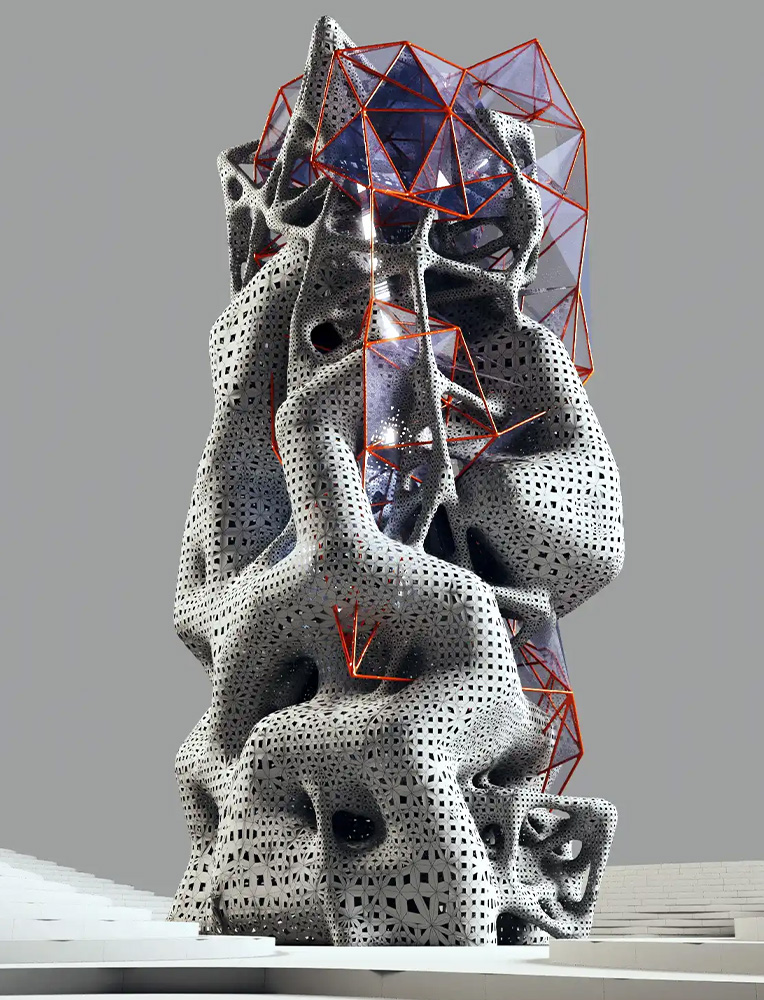

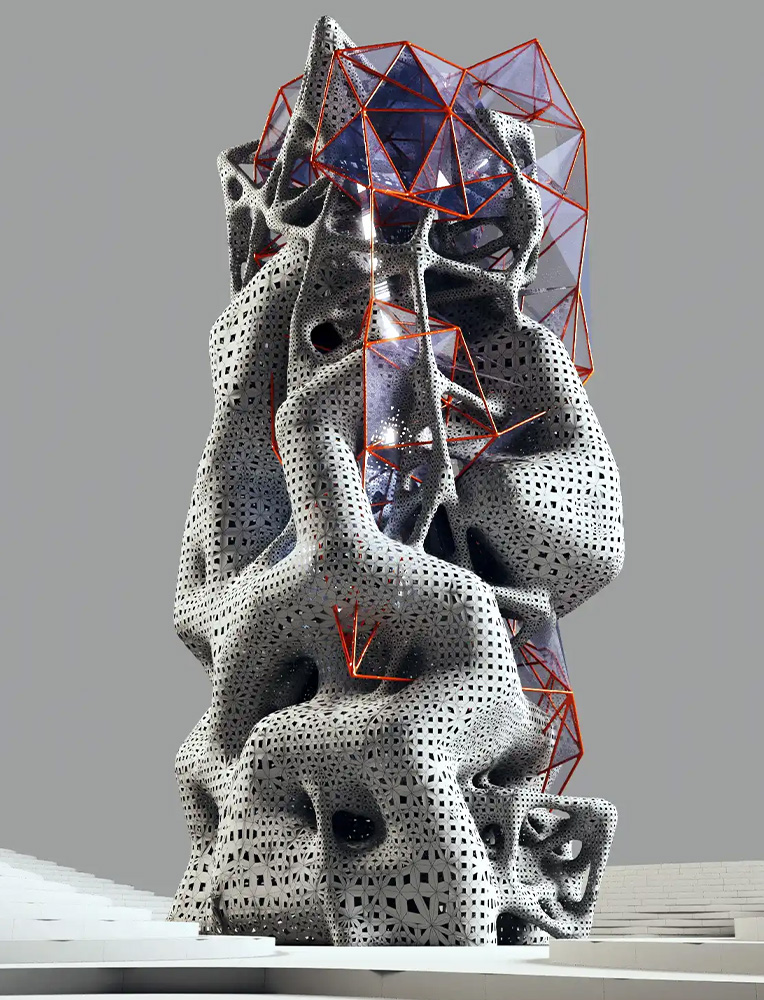

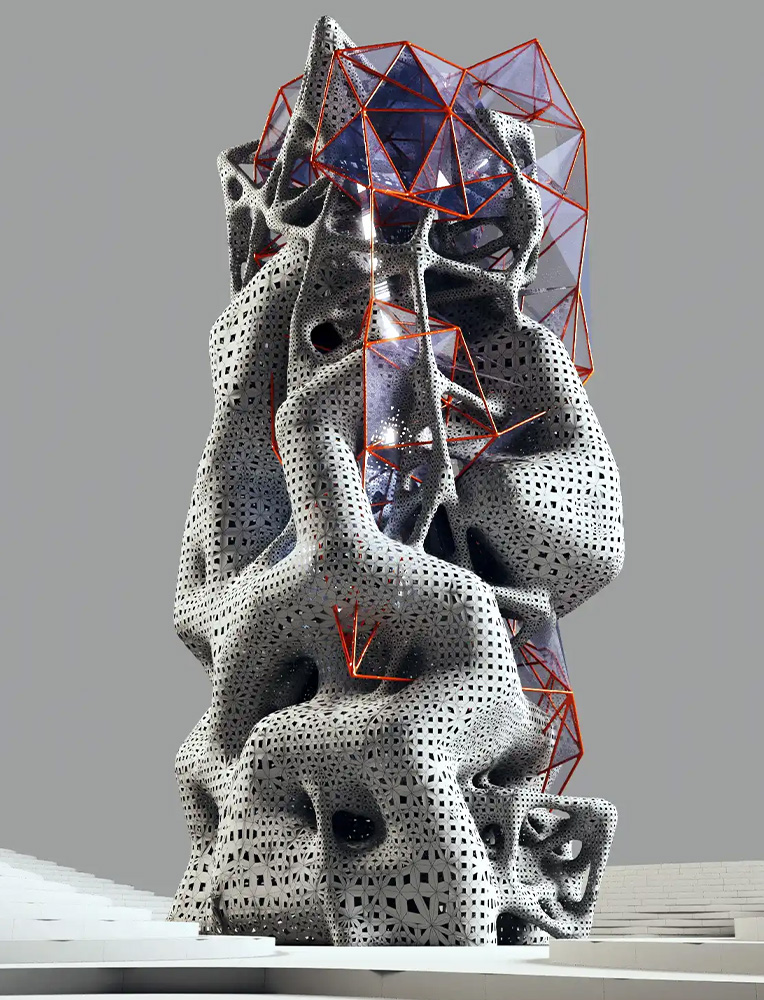

This workshop explores advanced Grasshopper workflows using parametric logic, data control, and hybrid modeling to create complex, performance-driven geometry.

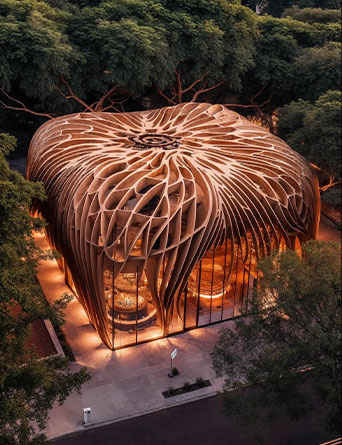

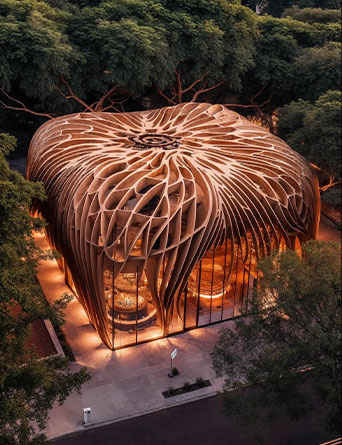

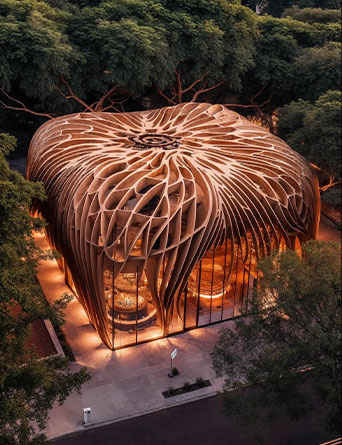

This workshop explores how designers can merge parametric design with generative AI to transform animations into site-integrated architectural visuals.

AI-Driven Architectural Design focuses on integrating AI tools to enhance creativity and streamline design processes in architecture.

This workshop explores advanced Grasshopper workflows using parametric logic, data control, and hybrid modeling to create complex, performance-driven geometry.

This workshop explores how designers can merge parametric design with generative AI to transform animations into site-integrated architectural visuals.

AI-Driven Architectural Design focuses on integrating AI tools to enhance creativity and streamline design processes in architecture.

This workshop explores advanced Grasshopper workflows using parametric logic, data control, and hybrid modeling to create complex, performance-driven geometry.

This workshop explores how designers can merge parametric design with generative AI to transform animations into site-integrated architectural visuals.

AI-Driven Architectural Design focuses on integrating AI tools to enhance creativity and streamline design processes in architecture.

Additive Footwear Design workshop will focus on using Houdini and Blender to create professional 3D printable footwear designs optimized for FDM and Resin printing technologies.

Your feedback helps us create better content for you

Intro + PAACADEMY Updates (10:40)

Introduction to the workshop - PAACADEMY Updates

Lecture (07:24)

3D Printing Footwear Insights

This presentation focuses on the constraints, manufacturing processes, and business models enabled by 3D printing footwear, discussing various technologies like FDM, SLA, and SLS, along with their applications, advantages, and limitations.

Shoe Last Creation Workflow (20:16)

Custom shoe lasts with Blender

This session discusses the process of creating a custom shoe last using foot scans, Blender tools, and open-source resources, with manual adjustments and optimization tips.

Procedural Footwear in Houdini (45:05)

Procedural footwear modeling with Houdini

This session focuses on using Houdini for procedural shoe sole design, covering node-based operations like importing geometry, adjusting attributes, creating extrusion, and generating textures dynamically.

Overhang and Texturing Workflow (55:34)

Overhang optimization in Houdini workflows

This session discusses optimizing overhangs, procedural texturing workflows, and dynamic adjustments in Houdini for 3D shoe design, ensuring alignment with printing requirements.

Mesh Refinement Workflow Houdini (42:26)

Mesh refinement and overhang management

This session discusses optimizing mesh surface groups, patching geometry holes, addressing overhangs, and refining texture smoothness and attributes in Houdini with procedural workflows for efficient shoe modeling and printing preparation.

3D Shoe Design Refinement (42:10)

Refining 3D shoe design workflow

This session focuses on finalizing the procedural workflow for 3D shoe design in Houdini, addressing issues like overhangs and texture mapping.

Procedural 3D Printing Techniques (59:37)

Procedural modeling for 3D printing

This session discusses incorporating low-poly modeling workflows and optimizing shoe designs for 3D printing using procedural techniques in Houdini.

Resin Shoe Design Techniques (40:04)

Resin shoe design workflows

This session focuses on creating a shoe design for resin printing using procedural workflows in Houdini, with an emphasis on cleaning geometry, generating lattices, and preparing for accurate printing.

SLA Lattice Workflow Optimization (35:04)

Lattice refinement and SLA optimization

This session focuses on refining lattice structures in SLA 3D printing to balance material efficiency and structural integrity, while addressing visualizer errors and optimizing Houdini workflows for shoe design.

Refined SLA Lattice Techniques (56:19)

Lattice design for SLA printing

This session focuses on advanced lattice design techniques in SLA 3D printing, emphasizing efficient geometry creation, material optimization, and resolving structural issues for footwear applications.

Customizing SLA Shoe Design (37:12)

Pressure mapping and SLA customization

This session discusses incorporating pressure mapping, variable lattice scaling, and SLA printing techniques to optimize structural efficiency and tailor shoe designs to individual user needs.

SLA Printing Support Techniques (38:25)

Designing supports for SLA printing

This session discusses techniques for creating support structures for SLA 3D printing, including effective ways to design connections and ensure printability.

Computational Design and Craft Insights (27:14)

Craft & computational design intersection

This session focuses on the growing intersection of computational design and traditional crafts, including discussions on design workflows and tool integration.

Learn how to use advanced parametric design tools, AI in design workflows and computational design in architecture from pioneers in the field!

Learn how to use advanced parametric design tools, AI in design workflows and computational design in architecture from pioneers in the field!

Save 20% Today! - Limited Time! - 50 Seats Only!

Dynamic Sketching: AI-Powered Architecture is not just a workshop; it's a creative breakthrough for architects, designers, and students ready to revolutionize the way they present their ideas.

No comments found.