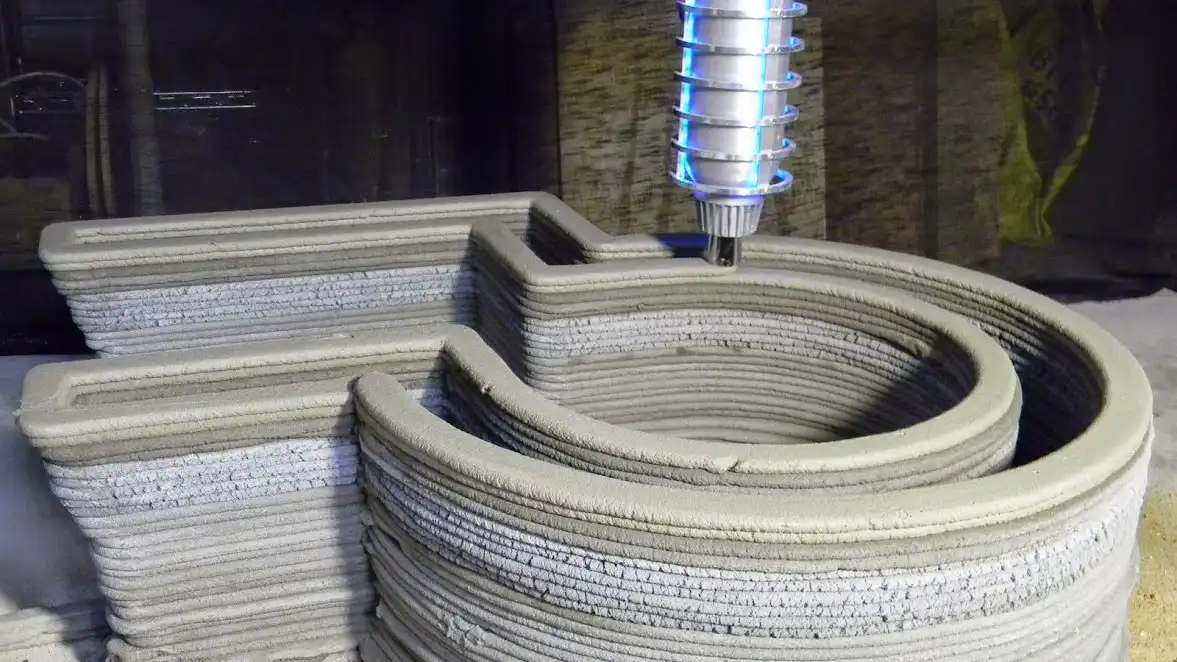

A promising building technique that has gained popularity recently is 3D-printed concrete. Using a computer program to build 3D objects, concrete layers are added on top of one another in 3D-printed concrete construction. Three essential components are needed for the 3D Printed Concrete (3DPC) process: printing equipment, a pumping mechanism, and a control system. The computer-based control system makes it possible to print both simple and complicated components. With the growing focus on sustainable building design, it is important to understand the performance of 3D printed components.

One of the rapidly 3D-printed concrete building components is the wall. Printed walls can vary based on the printing technique, layer design, and structural function. Some are filled, solid, strong walls, and some are hollow or cavity walls. As a part of the main structure wall performance plays a vital role. Therefore, it is important to know the thermal energy performance of the structures developed using the innovative 3DPC technique. Thermal characterization of walls is fundamental for the assessment of the energy performance, and thermal insulation plays an important role in performance enhancements.

3DPC technologies are still in the early stages and undergoing extensive research and development to utilize their full potential and realize environmentally friendly materials that can make future buildings more sustainable and environmentally friendly. The numerous advantages of 3DPC have motivated many companies to invest in and capitalize on these technologies. Accordingly, the industrial sector has witnessed a successful demonstration with promising potential to be explored in the near future. For example, CyBe, Apis Cor, and Winsun are examples of many companies that develop and provide 3DPC solutions and are already in the construction market, employing 3DPC in different construction projects around the world.

The structures feature solid walls made with a 3D printing technique. One of the pioneers in printing houses with solid walls is ICON by introducing project East 17th Street Residences in Texas, USA. Homes are made layer by layer with printed solid walls, providing durability and strength. In houses ground-floor walls are built using ICON’s Vulcan printing system, which uses a robotic armature to layer Portland-cement-based material Lavacrete into surfaces. This process is long-lasting and effective in providing resistance to extreme weather conditions. Some of the benefits of solid walls are increased speed, precision, and reduced material waste as compared to conventional walls.

Walls with hollow cores provide an opportunity for the builder to fill the hollow cores with different infills to improve their function and performance. Filling with potential insulation materials increases the thermal performance of walls. Due to the hollow core wall's high thermal mass, the structure that enables materials to absorb, store, and release heat, hollow-core wall possesses the ability to efficiently transfer large amounts of heat and keep buildings cool in the summer. Habitat for Humanity's 3D Printed Homes in Virginia, USA, are built with this technique that helps to reduce material usage and provide enough space for insulation and utilities in homes.

The design of infused pattern walls encloses internal grid-like patterns. These walls are infilled and serve as a load distributor in the structure. Walls are printed by following mathematical geometrical patterns, such as hexagonal, diagonal, or gyroid infill patterns, mainly depending on the objectives of the design strategy. Infused pattern walls are lightweight, customized, and efficient structures in a house. Apart from structural integrity, these walls play a vital role in thermal and acoustic insulation. These walls also provide a wide range of organic and biomimetic forms. The insulation materials like mineral wool, rockwool, and fiberglass, and any type of insulation significantly influence the U-values of 3D printed walls. In turn, this will lead to reduced energy consumption and lower heating and cooling costs, and improve the overall performance.

The sandwich walls are designed in two layers, often called multi-layered walls due to the two layers with space in between. Inner and outer layers are printed with some space to provide insulation between the walls. This provides thermal performance and energy efficiency. This design of the wall establishes the potential of 3D printing in sustainable construction and housing. Project Milestone at Eindhoven, Netherlands, introduced the first habitable 3D printing house with sandwich walls. The printed facade is constructed separately from a load-bearing inner wall and a loose outer wall with insulation material in between, giving the concept a recycling character and allowing the printed parts to be reused in the future. A wide range of insulation materials is available, including mineral, synthetic, and bio-based natural insulations. Bio-based insulations like straw and rice husk are proven to be environmentally friendly, cost-effective, and reusable materials.

With the evolution of 3D printing, architects and engineers can create unique and customized building facades and decorative elements. Façade walls are printed in complex textures, curved, and in unique patterns that were not easy to achieve with conventional construction techniques. Installation of these facade walls and wall panels is cheaper and faster than older methods. Façade walls serve as an integrated building component with decorative, structural, and functional features. Experiments are being done with different eco-efficient materials to print façade blocks and panels for walls. Organic and bio-based façade blends traditional and modern technology as well as increases the aesthetic appearance of 3D printed structure. This leads to a sustainable and visually remarkable architecture.

.webp)

Since 3D printing technology executes the printing project in a layer-by-layer approach, repeated unit design is preferred. The infill structure of the exterior walls, which is responsible for heat losses into or out of the building envelope, is designed to minimize heat transfer for better building energy efficiency. The green wall concept is also useful in these scenarios, where external walls are used for a passive energy system via vegetation. 3D printing has been identified as a future development in the construction sector due to its potential to support sustainable design. Since the building envelope accounts for 50–60% of the total heat transfer, improving thermal insulation is a cost-effective strategy for improving energy efficiency. Printed walls with multiple choices of infills and geometry give freedom to move towards sustainability.

As 3D printing continues to revolutionize design and sustainability, there's never been a better time to explore its potential. Whether you're interested in how to use advanced parametric design tools to design dynamic facades or print innovative wall panels, PAACADEMY offers in-depth workshops covering these techniques. For a comprehensive learning experience, check out the 3D Printing Workshop Bundle—a curated collection of courses designed to take your skills from concept to fabrication.

You must be logged in to comment.