One of the most pressing and enduring issues facing the world today is the shortage of affordable housing. Nearly 100 million people are homeless, and over 1.6 billion people need proper housing, according to UN-Habitat. This increasing demand is difficult for traditional construction methods, which are labor-intensive, time-consuming, and resource-intensive, particularly in poor countries and areas that are prone to disasters.

3D-printed housing, an approach to building that provides a productive, expandable, and more affordable substitute. 3D printing, which was once thought to be experimental or specialized, is now being used with unexpected effectiveness in low-income housing, and the outcomes are revolutionary.

In the construction industry, 3D printing, also known as additive manufacturing, is the process of layer-by-layer extrusion of building materials through massive robotic printers, using materials like concrete and earth-based composites. These devices print structural walls, floors, and occasionally entire building shells by using pre-coded digital models.

The accuracy, speed, and economy of 3D-printed buildings are its main selling points. Up to 80% less building waste can be produced by printing some structures in less than a day. Curved walls, organic shapes, and modular forms are simply possible, and there is a significant reduction in the demand for physical work. More significantly, this method tackles housing's triple crisis of affordability, accessibility, and climate resilience.

3D-printed housing initiatives are changing our perception of housing for the poor. In addition to showcasing the technical prowess of large-scale 3D printing, these case studies demonstrate how adaptable technology is to a variety of climatic, cultural, and economic contexts. Architects, non-governmental organizations, and digital entrepreneurs from North America, Africa, and Asia are implementing this in practical, low-income settings with noticeable results.

The globe saw the first 3D-printed low-income family community in Nacajuca, Tabasco, Mexico. The initiative was created by the non-profit New Story, the construction tech company ICON, and the local housing NGO Échale. They used a proprietary Lavacrete material and the Vulcan II printer to deliver 50 dwellings.

There were two bedrooms, a kitchen, a bathroom, and a covered porch in each 500-square-foot home. Homes were created to withstand local climate extremes, such as earthquakes and floods, and were printed in 24 to 36 hours

This was the first time a 3D-printed housing project was deployed at community scale, demonstrating the technology’s potential for real-world, long-term housing solutions. The dwellings, which were co-designed with local families, are inclusive since they represent functional needs and regional cultural values.

Malawi became home to Africa’s first 3D-printed house through a collaboration between 14Trees, a joint venture of Holcim and CDC Group, and COBOD, a Danish 3D printing company. The UN Affordable Housing Standards were met by the little, low-carbon cement house, which was printed in about 12 hours.

The building cut carbon emissions by more than 70% when compared to conventional brick buildings. This project's success has sparked more 3D-printed housing initiatives in Zimbabwe and Kenya, which could transform the cheap housing market in sub-Saharan Africa.

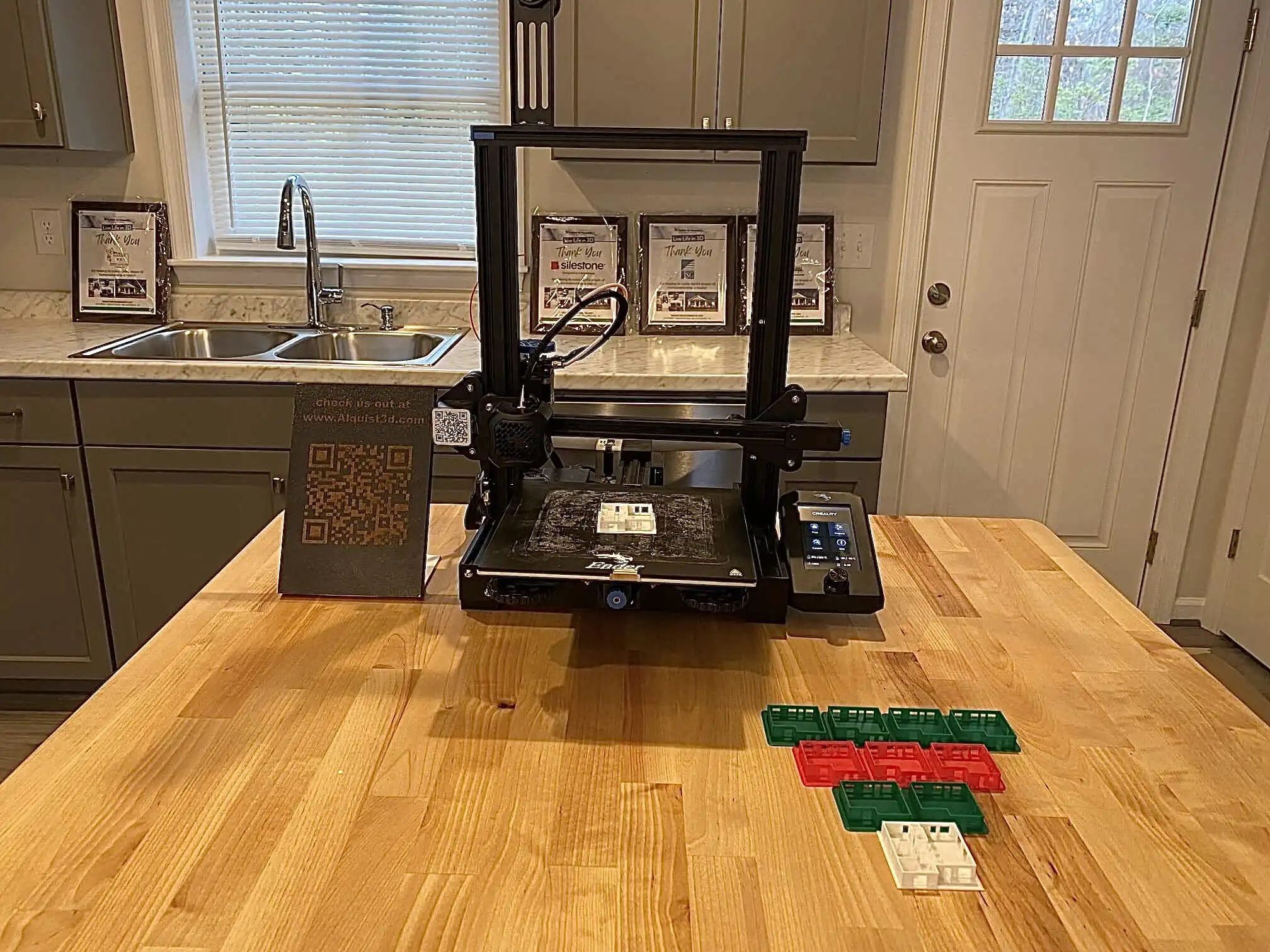

Alquist 3D and Habitat for Humanity collaborated to finish the nation's first owner-occupied 3D-printed home in Williamsburg, Virginia in the USA. The 1,200-square-foot home was constructed with a gantry-mounted concrete printer, which used finished concrete interiors instead of drywall.

With its superior thermal performance and 15% cost reduction, this design strategy reduced energy costs by 30%. Interest in such affordable, disaster-resistant homes has increased throughout the United States as a result of this home's success.

On the campus of IIT Madras, Chennai-based business Tvasta Manufacturing Solutions debuted India's first 3D-printed house in 2021. In just 21 days, the 600-square-foot prototype was built using a concrete mix that was specially designed for the environment of India. The study demonstrated how 3D printing may help mass housing, with 80% less waste and 30% faster production times.

One entirely printed residential building was constructed on-site in Stupino, Russia, in 2017 by the Russian 3D printing business Apis Cor, in a single day. Even in extremely cold weather, the entire building process was carried out on-site with Apis Cor's mobile printing technology.

With the help of the machine's 360-degree robotic arm, the structure was printed using a special concrete mix that was engineered to endure the severe Russian winters. It also featured monolithic formwork and curved walls. At the time, it was less than $10,000 to build, including windows, roofing, insulation, and interior finishing, which established a new standard for pricing in 3D-printed homes.

In addition to its speed and cost-effectiveness, this project was noteworthy for its smooth integration of utilities, insulation, and aesthetics into a single, efficient procedure. By proving that 3D printing can be used for emergency and low-income housing in cold climates, Apis Cor's invention positioned 3D printing as a potentially revolutionary solution for affordable housing in areas with harsh weather.

The most popular material for 3D-printed homes is concrete, but new developments are broadening the selection. The TECLA prototype, developed in Italy by Mario Cucinella Architects and WASP, was a biodegradable, zero-waste house built with clay that was gathered locally. Mighty Buildings is testing composite polymers and light-stone materials in California to provide prefabricated modular homes.

Regarding sustainability, 3D-printed homes can be made with energy-efficient designs, produce less trash, and require less raw resources. Some use rainwater harvesting devices, solar panels, and passive cooling. 3D-printed homes fit in nicely with social and environmental requirements as the movement toward net-zero structures gains momentum.

In the worldwide endeavor to address the housing crisis, 3D printing has progressed beyond the prototype stage to become a viable option. The technology is demonstrating its versatility and scalability across cultures, regions, and income levels, whether it is being used in a rural home in Virginia, a refugee shelter in Kenya, or a cyclone-resistant housing in Tamil Nadu.

The way the world builds and for whom it builds, could be revolutionized by 3D-printed houses with careful planning, governmental backing, and R&D investment. Robots, algorithms, and sustainable materials will be used more and more by governments, architects, and urban planners in the coming future to create better, more equitable buildings.

You must be logged in to comment.