In an era where technology is advancing at an unprecedented pace, 3D printing—also known as additive manufacturing—has emerged as one of the most transformative innovations of the 21st century. At its core, 3D printing is a process that allows the creation of three-dimensional objects layer by layer, using digital models as blueprints. Unlike traditional subtractive manufacturing, which involves carving out a final product from a solid block of material, 3D printing builds structures from the ground up, drastically reducing material waste and enabling an entirely new way of thinking about fabrication.

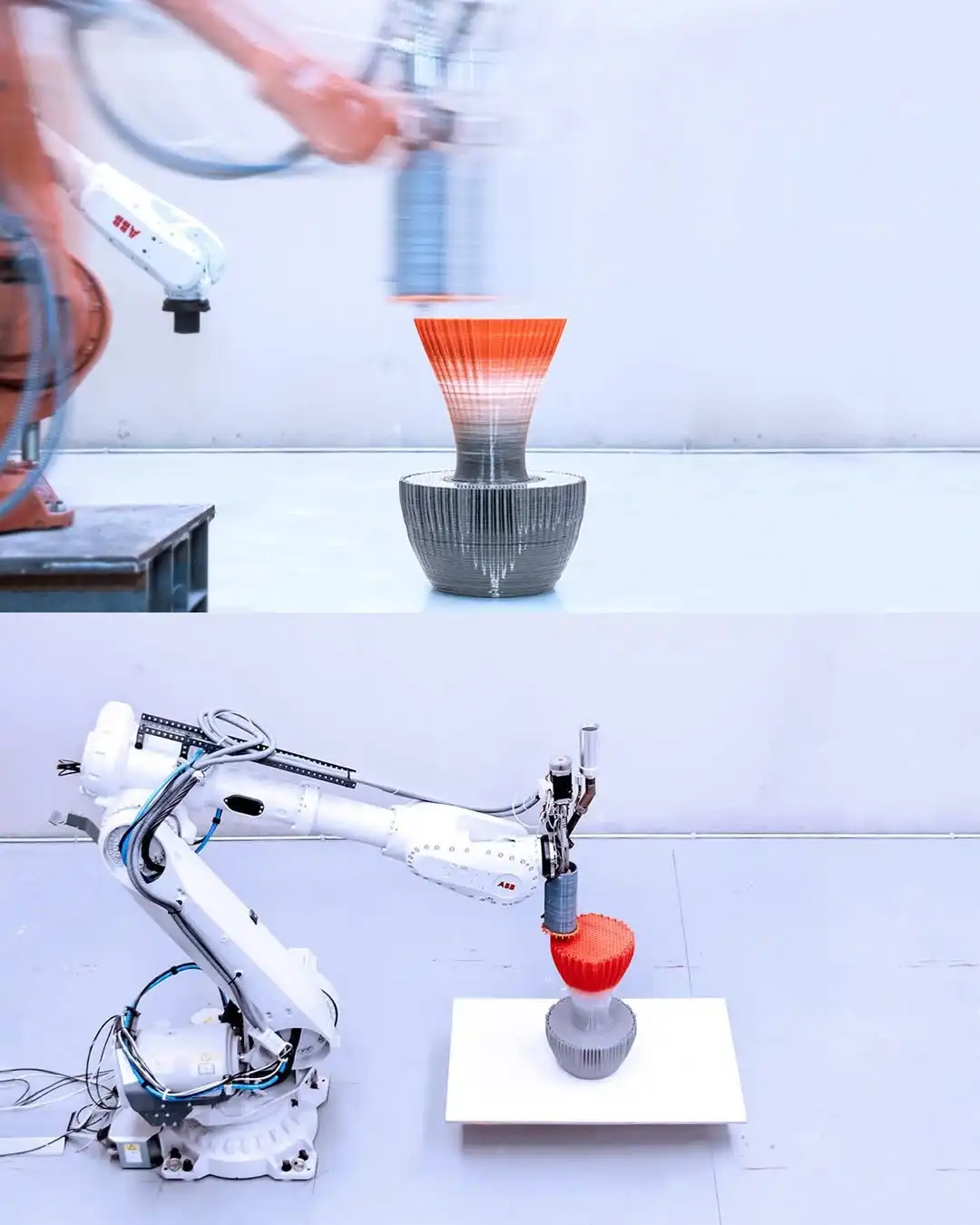

The application of this technology in construction is particularly revolutionary. By extruding concrete, clay, or other composite materials through robotic arms, large-scale 3D printers can construct entire buildings with precision and efficiency. This process eliminates the need for excessive manual labor, reduces construction time, and introduces the possibility of creating complex, organic forms that would have been nearly impossible to achieve through traditional building methods. More importantly, 3D printing has opened doors to solving some of the most pressing challenges in urban development, from the global housing crisis to the necessity of sustainable and resilient architectural solutions.

The origins of 3D printing trace back to the early 1980s when Charles Hull, an American engineer, invented the first working 3D printer based on a technique called stereolithography. This method utilized ultraviolet lasers to harden the liquid resin, creating three-dimensional objects layer by layer. Hull’s breakthrough laid the foundation for what would eventually evolve into one of the most groundbreaking manufacturing techniques of our time.

As the technology advanced, researchers and engineers began experimenting with different materials and printing methods. The late 1990s and early 2000s saw the emergence of fused deposition modeling (FDM) and selective laser sintering (SLS), making 3D printing more accessible across industries. While initially reserved for prototyping small-scale objects in industries such as aerospace and medicine, construction companies soon realized the potential for scaling up these technologies to build homes, offices, and even entire neighborhoods. Today, 3D printing in construction is no longer a futuristic concept—it is a tangible, viable solution to many of the challenges facing the architectural, engineering, and construction (AEC) industry.

.webp)

The rapid urbanization of cities worldwide has led to an increasing demand for affordable, high-quality housing. According to the United Nations, nearly 3 billion people will require housing solutions by 2030, creating a critical need for efficient, sustainable, and cost-effective construction methods. This is where 3D printing enters the scene as a game-changing force. Unlike conventional construction techniques that require significant amounts of labor and raw materials, 3D printing significantly reduces waste, accelerates building timelines, and allows for customized architectural solutions tailored to specific environments.

Beyond Earth, 3D printing is revolutionizing construction. With NASA and private companies like ICON exploring automated 3D-printing systems for lunar and Martian habitats, the prospect of printing structures on other planets is becoming increasingly feasible. Using in-situ resources—such as lunar regolith or Martian soil—eliminates the need for transporting heavy materials from Earth, making space colonization a more realistic possibility.

For architects, 3D printing is not just an alternative construction method—it represents an entirely new paradigm in design and fabrication. In the past, architectural forms were often limited by the constraints of traditional construction techniques, forcing designers to think within the bounds of what was feasible to build. However, with 3D printing, these limitations are rapidly dissolving, allowing architects to push the boundaries of creativity and experimentation.

One of the most significant advantages of 3D printing in architecture is its ability to materialize complex geometries with minimal material waste. Organic and biomimetic structures, which once required extensive manual labor and expensive fabrication techniques, can now be realized with a simple digital model and a robotic arm. This allows for a seamless fusion between artistry and engineering, enabling architects to create sustainable, highly efficient structures that adapt to their environments.

Over the past decade, the construction industry has witnessed a significant influx of capital into 3D printing technologies, reflecting a growing confidence in its potential to revolutionize building practices. In 2022, the global 3D printing construction market was valued at approximately $3.5 billion, with projections suggesting a remarkable growth to around $523.3 billion by 2030.  This surge is driven by the technology’s promise to enhance efficiency, reduce waste, and offer innovative design possibilities.

Investments have not been limited to startups; major construction firms are actively investing in 3D concrete printing processes. Companies like Saint-Gobain and Holcim Group have acquired stakes in 3D printing firms, focusing on developing 3D-printed building materials and components. Additionally, the number of funded companies in the 3D printing construction sector has grown, with 58 companies receiving funding, 25 of which have secured Series A funding.

This substantial capital allocation underscores the industry’s commitment to integrating 3D printing into mainstream construction, aiming to address challenges such as housing shortages and the demand for sustainable building solutions.

Several pioneering companies are leading the way in applying 3D printing technology in construction. These firms have demonstrated that large-scale additive manufacturing is not just a concept but a practical and transformative solution to modern architectural challenges.

ICON: Based in the United States, ICON has developed Vulcan, a large-scale 3D printer capable of constructing homes in under 24 hours. The company has collaborated with NASA on space habitats and has built entire neighborhoods of 3D-printed homes for low-income families.

Apis Cor: Known for printing the world’s first fully permitted 3D-printed house in Russia, Apis Cor has pioneered robotic construction technology, pushing the boundaries of automated building techniques.

COBOD: A Danish company specializing in large-scale construction printing, COBOD has worked on numerous international projects, including the first 3D-printed wind turbine tower.

Peri: A German construction company that has successfully completed multiple 3D-printed residential projects in Europe, demonstrating the scalability and efficiency of this technology.

At PAACADEMY, our mission has always been to equip architects, designers, and engineers with cutting-edge knowledge and tools that define the future of the built environment. Recognizing the transformative impact of 3D printing, we have launched specialized workshops that delve deep into the mechanics, applications, and potentials of this groundbreaking technology.

Our 3D-printing workshops, such as 3D Printing Ceramics 2.0, 3D Printing Innovations with FDM, and 3D Printing Construction, provide participants with hands-on experience using tools like Rhino, Grasshopper, and Cura. By fostering a community of forward-thinking professionals, PAACADEMY is not just an educational platform but a movement that embraces the future of digital fabrication and architectural innovation.

As we look ahead, the role of 3D printing in construction will continue to expand, unlocking new opportunities for sustainability, automation, and design freedom. With the potential to integrate AI-driven generative design, robotic assembly, and on-site fabrication, the construction industry stands on the brink of an era where buildings are not merely erected but printed with precision and adaptability.

Just as the printing press revolutionized the dissemination of knowledge, 3D printing is revolutionizing the very fabric of our cities. The question is no longer whether this technology will define the future of architecture but rather how quickly we can embrace its potential to create a more efficient, resilient, and imaginative built environment.

You must be logged in to comment.