In contrast to conventional building materials, 4D materials add the fourth dimension, time, to 3D material behavior by gradually responding to environmental stimuli like heat, moisture, or light. 4D materials stick out as material science and digital technology become more integrated. The built environment could now undergo a transformation thanks to these intelligent, responsive materials.

4D materials give up a new creative frontier for architects and designers who must contend with energy demands and the requirement for intelligent buildings. 4D applications are growing quickly, ranging from climate-responsive facades to self-assembling shelters.

This article examines the varieties of 4D materials, their functions, and its most potential applications.

The introduction of 4D materials, a revolutionary invention that incorporates time into the material performance equation, is causing a radical change in architecture. In contrast to traditional building materials, 4D materials can alter their structure, form, or behavior over time in response to environmental cues including light, moisture, heat, and even pH levels. They are dynamic, programmable, and responsive. These qualities are essential for the built environment of the future and require sustainability and adaptability.

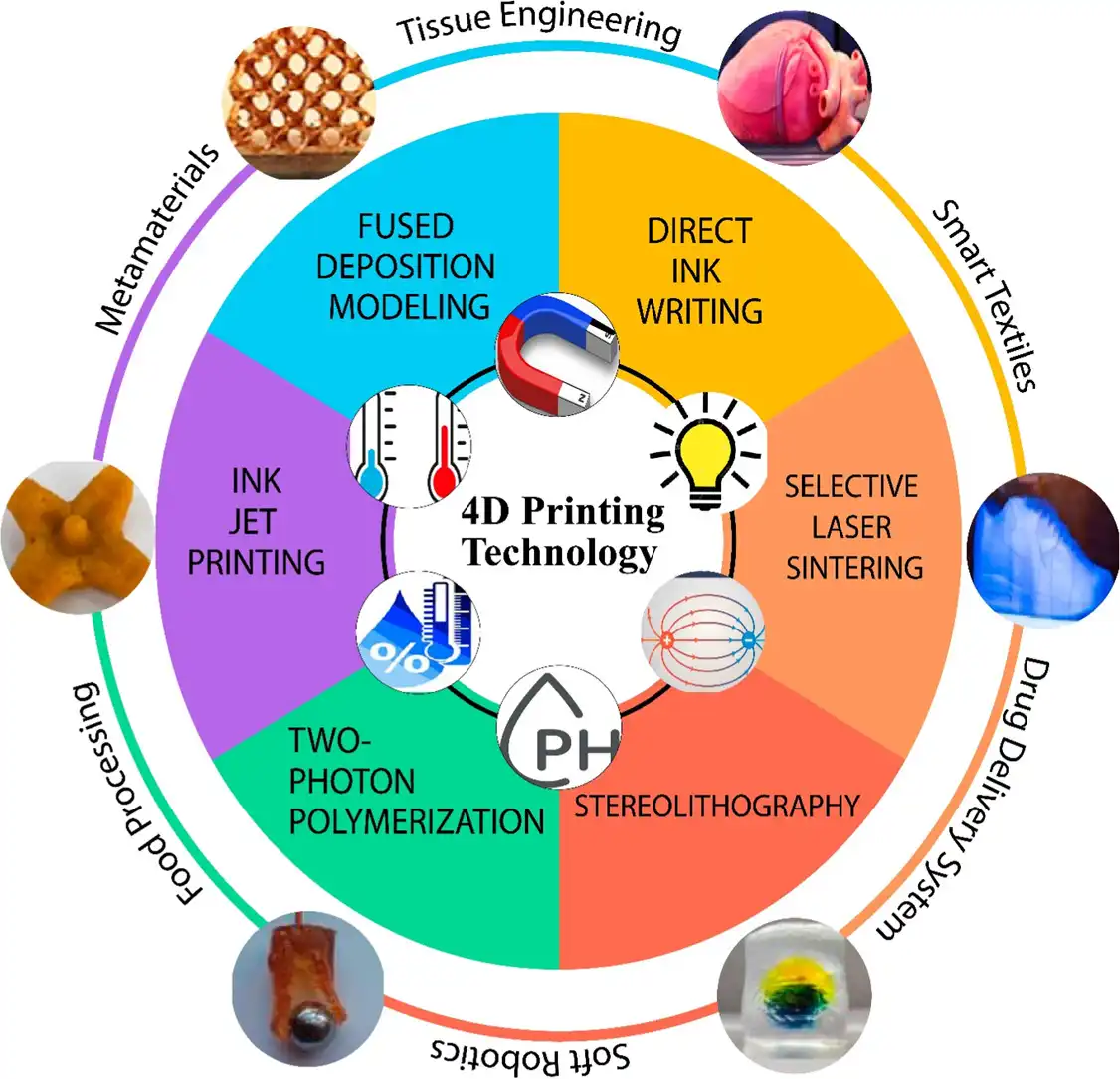

4D materials, which were created at the nexus of material science, 3D printing, and bioengineering, are already showing promise in the fields of infrastructure, product design, architecture, and aerospace. 4D materials provide designers and engineers a sustainable solution that is intelligent and energy-efficient for dealing with the climate issue and material misuse.

The primary attraction of 4D materials is their capacity to react to outside stimuli without the need for mechanical assistance. Specialized composites are used to manufacture these materials, many of which can be programmed utilizing multi-material fabrication or 3D printing techniques. This enables designers to code the behavior of materials in specific scenarios.

One well-known example is the application of Shape Memory Alloys (SMAs), like Nitinol, which, when exposed to particular temperatures, revert to a predefined shape. These alloys are currently undergoing testing for seismic dampers in buildings and kinetic façade systems.

In a similar vein, plastic-based substances known as Shape Memory Polymers (SMPs) undergo deformation at one temperature and regain their original shape at another. They are perfect for interior parts or surfaces that respond to changing temperatures.

Hydrogels, another class of smart materials, expand or contract in response to moisture. These could be used in passive construction systems such as roofing membranes or self-regulating wall panels. Liquid crystal elastomers (LCEs), which respond to heat and light, are also becoming more popular for uses such as energy-efficient shading systems or sun-tracking louvers.

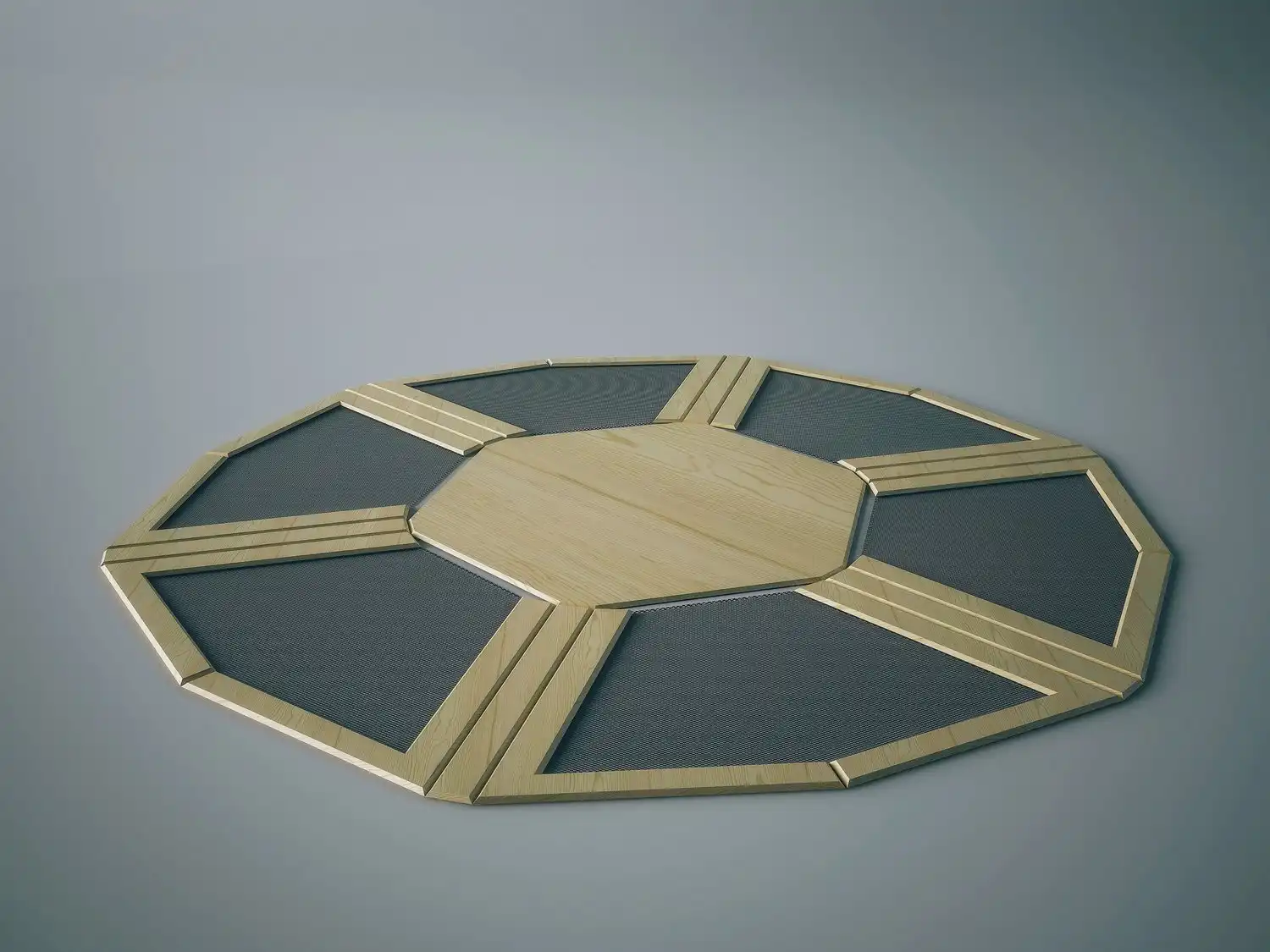

The creation of flexible building skins is one of the most exciting applications of 4D materials in architectural design. Depending on variations in sunlight, temperature, humidity, or air pressure, these dynamic façades can swell, shrink, curl, or fold. Building's skin reacts passively rather than through intricate mechanical systems, improving thermal performance and lowering energy usage.

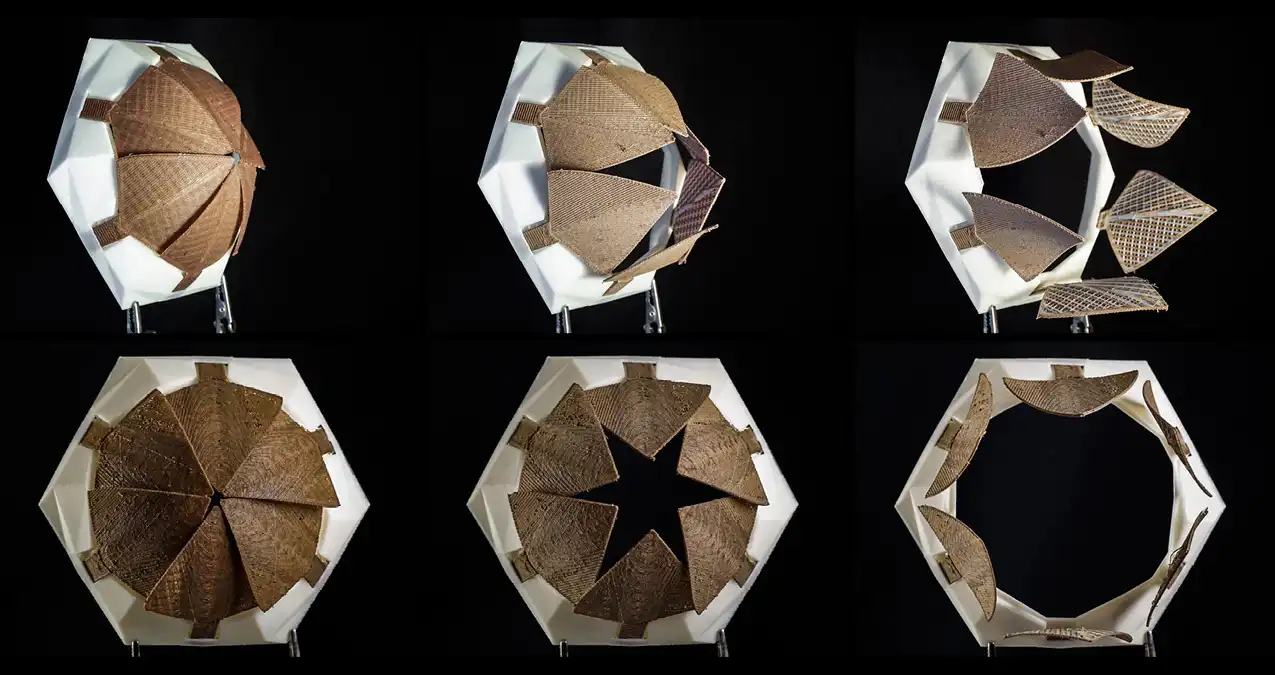

The HygroSkin Pavilion, created by Achim Menges and the Institute for Computational Design and Construction (ICD) at the University of Stuttgart, is a well-known example. This building mimics the movement of pinecones by using thin plywood panels that spontaneously curl open or close depending on humidity conditions. A climate-responsive façade system without motors, sensors, or energy input is produced by this biological reaction.

Buildings that can passively adapt to changing environments are becoming increasingly important as cities get denser and climate extremes intensify. By reducing operating energy requirements, smart façades made of 4D materials mark a significant advancement in sustainable building.

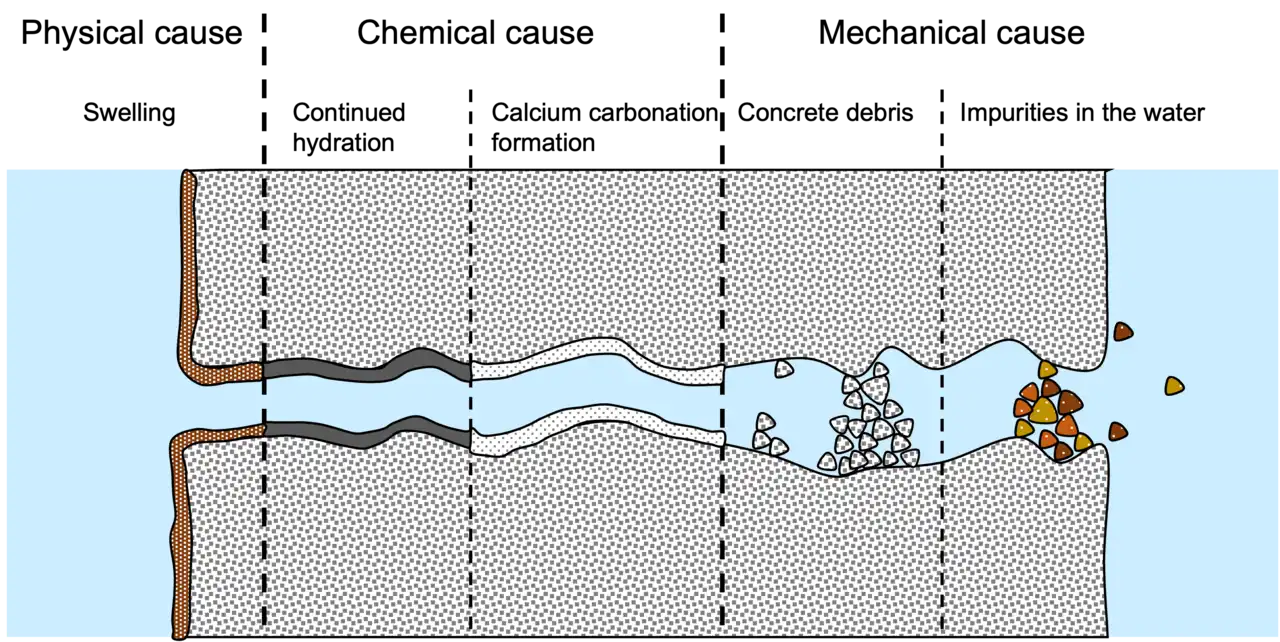

The longevity and safety of buildings and bridges can be significantly impacted by concrete cracks. Researchers at the Netherlands' Delft University of Technology have created a kind of bio-concrete that is embedded with bacteria that produce limestone in order to address this issue. Water seeping into a fracture causes the bacteria to become active and start sealing it, thereby healing the material.

This strategy has the potential to completely transform infrastructure upkeep, particularly in isolated or dangerous areas. Addressing structural damage with smart materials automatically lowers costs and increases long-term resilience, two important benefits for cities that are prepared for the future.

Climate-responsive interiors that adapt to temperature and occupancy can be made inside buildings using 4D materials. Consider using SMPs or other responsive materials for wall panels, ceilings, or partitions that change shape in response to changes in room temperature. This would eliminate the need for mechanical systems and provide thermal comfort, better ventilation, and even glare control.

Applications where programmable furniture and partitions react to usage patterns, folding away when not in use or growing when occupancy increases, have been investigated by Skylar Tibbits, founder of MIT's Self-Assembly Lab. Construction speed and transportation efficiency which are crucial in rural areas, refugee camps, and catastrophe areas, is also being considered. This gives the idea of adaptable, multipurpose elements that are perfect for classrooms, co-working spaces, or interior spaces in homes.

For instance, Autodesk and MIT's Self-Assembly Lab collaborated to create a 4D-printed pipe system that, when immersed in water, bends and closes itself. This idea might be expanded for field hospitals, deployable shelters, or flat-packed infrastructure that only activates when required, doing away with the requirement for specialized workers or equipment on location.

Biomimicry is the technique of imitating natural phenomena in design. It has emerged as a major factor in the development of 4D materials. Pinecones that open in dry weather, flowers that blossom in sunshine, and vines that curl when touched are just a few examples of the responsive systems found in nature. Using synthetic or hybrid materials, 4D materials mimic these reactions, enabling architects to use nature's intelligence in their designs.

These days, architects create forms and behaviors that are energy-efficient and practical by using computational design and simulation technologies. 4D architecture gets closer to developing living structures that change, adapt, and evolve. All achieved without the need for mechanical support.

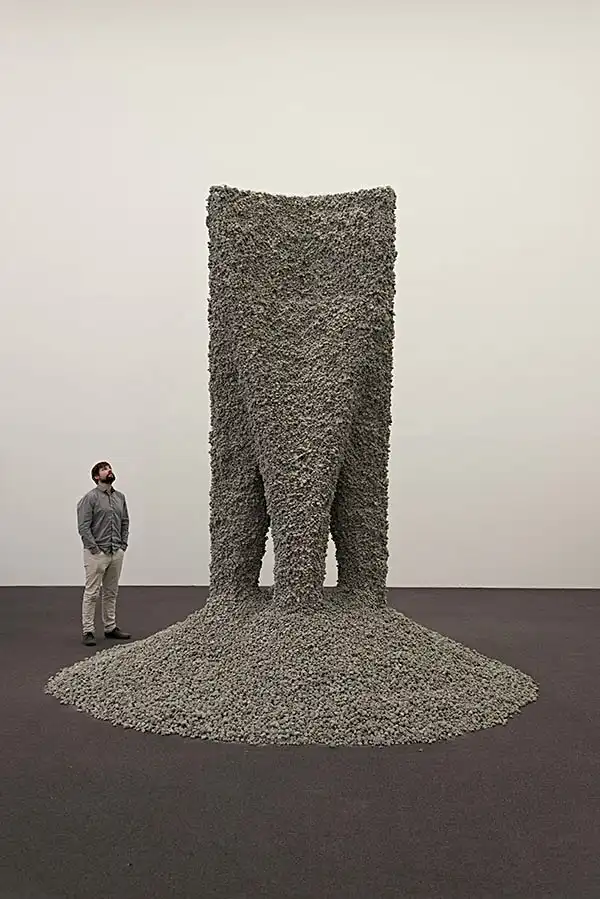

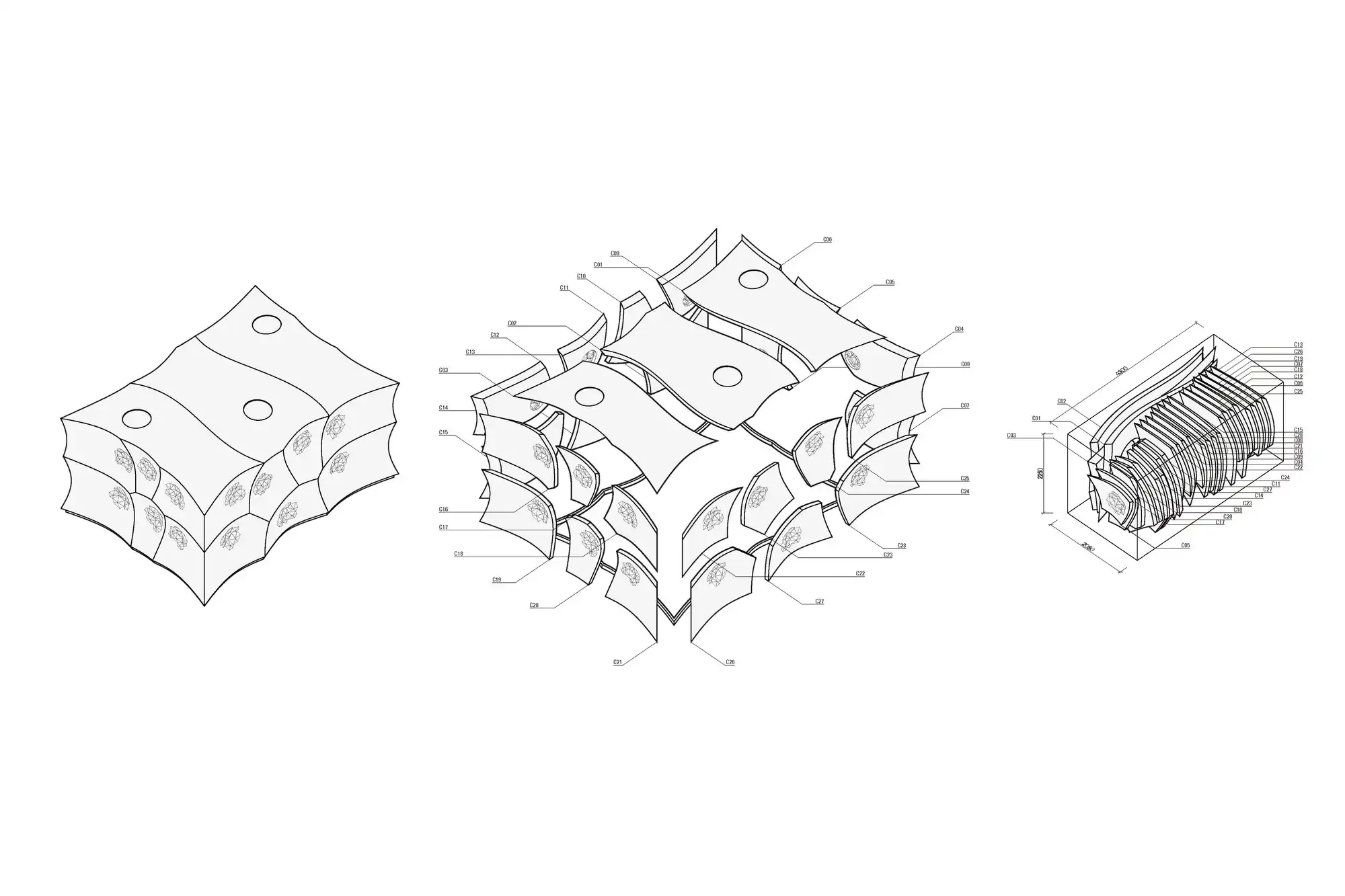

Rock design. Courtesy of Self-Assembly Lab, MIT.

There are many advantages to using 4D materials in building. By using fewer heating, ventilation, and air conditioning systems, they can improve energy efficiency. By reducing material waste and getting rid of complicated mechanical parts, they promote sustainability. Additionally, they present fresh design options for dynamic spaces that satisfy users' needs in real time.

But there are still difficulties. Research and prototyping are still ongoing for many 4D materials. Challenges include cost-effective manufacturing, scalability for huge structures, and durability under numerous stress cycles. Additionally, programmable or bio-reactive materials are not yet covered by building laws and regulations, raising safety and legal concerns.

Numerous organizations are at the forefront of 4D material research and development. Leading the way in 4D printing, the MIT Self-Assembly Lab is creating anything from transformable furniture to smart textiles. Bio-inspired pavilions made of responsive materials were first introduced by the ICD/ITKE at the University of Stuttgart. While ETH Zurich investigates robotic manufacture and adaptive systems, TU Delft is developing self-healing concrete and microbial buildings. The large-scale implementation of 4D materials is being actively shaped by these labs.

4D materials symbolize a new way of thinking about design. We may now imagine buildings as dynamic systems that engage with their environment, change with their users, and develop over time, rather than as static structures

4D materials will probably become essential to sustainability as the technology advances, costs come down, and standards are established. By combining responsiveness and design, we are creating structures that are not just for the here and now, but also adapt and evolve over time.

You must be logged in to comment.