Now is the perfect moment for automated construction technologies to play a significant part in enabling the digital revolution of construction to fully take shape. Significant technological developments have accompanied the intriguing evolution of construction automation. These developments have revolutionized construction work over time, improving accuracy, safety, and efficiency. It's a fascinating field with the potential to completely alter the dynamics of infrastructure and building development.

A futuristic panorama of construction automation relies on automation in a variety of ways, including automated digital design and analysis procedures, automated construction documentation generation, and, eventually, automated construction itself. The success of the construction industry in meeting its dual challenges of the twenty-first century, the high demand for buildings and infrastructure and the requirement for sustainability throughout the entire lifecycle, will depend on the automation of construction processes, whether they are used for on-site construction robotics or off-site prefabrication that emulates advanced manufacturing best practices.

Robots and automated tools flying around a construction site may seem like a sci-fi fantasy, but the truth is that mechanized, automated construction concepts have been demonstrated for centuries, and strategies essential to their deployment have existed for millennia. From the prefabrication methods used to construct the Terracotta Army in third-century BCE China to the prefabricated panels erected on-site for homes in Berlin in the 1920s, the earliest instances of off-site building are separated by more than 2,000 years.

However, the first industrial robots were created in the 1950s, and the automobile sector did not use them until the 1960s when modern construction automation with robotics really took off. In the 1960s and 1970s, construction robotics started to emerge, and factory automation expanded throughout the industrial world. Japan developed construction automation and robots in the 1970s and 1980s in response to a manpower shortfall in the construction industry brought on by an aging population and disengaged younger workers. For excavation, material handling, concrete placement and finishing, fireproofing, earthworks, rebar placement, and other construction tasks, Japanese architecture and engineering firms like Shimizu Corporation, Obayashi Corporation, and Takenaka Corporation developed robots and remote-controlled machinery.

However, a revival of construction automation is currently taking place, supported by partnerships between governments, corporations, and academic institutions. Rapidly developing robotics and Internet of Things (IoT) technologies, along with the robust data and advanced architectural design and data-management capabilities provided by BIM (Building Information Modeling) and artificial intelligence-infused generative design approaches, are combining to drive the digitalization of construction and its convergence with manufacturing techniques. Industrial robots can now be used in the construction industry thanks to innovative workflows that connect design and robotic fabrication processes and lower-cost technology.

As we enter the year 2025, the construction industry is undergoing an extraordinary technological revolution with construction robots. According to a MarketsandMarketsTM analysis, the worldwide construction robot market was estimated to be worth $420 million in 2021 and is expected to grow rapidly to $765 million by 2026. Mighty Building, Inc. Introduced a 40+ unit community of 3D printed ZERO NET ENERGY HOMEs in California, USA. This type of future-driven project initiates a sustainable housing market developed with innovative automated tools.

Advanced Automation: Self-sufficient construction equipment is now a reality, thanks to advancements in sensors, GPS, and machine learning, reducing the need for human assistance.

3D Printing Revolution: The construction industry has undergone a complete transformation with the arrival of 3D printing technology, enabling the creation of entire structures through additive manufacturing processes. 3D printing made it possible to imagine big and bring to life complex architectural designs with accuracy and precision.

AI and Machine Learning Integration: The incorporation of artificial intelligence and machine learning into construction robots has allowed them to make decisions on their own, optimize routes, and increase operational efficiency.

Increased Safety Measures: Robots have greatly improved safety in construction by managing risky jobs and lowering dangers to human workers.

Off-site Automation: These practices move construction processes off-site and into factories within a familiar and controlled environment that can be optimized to take advantage of automation, industrial robotics, digital production workflows, and design for manufacturing and assembly strategies. Although factory automation requires a significant initial investment, it can ultimately save time, money, and resources while enhancing quality assurance and control and creating safer, more comfortable working environments for employees by removing many of the repetitive tasks involved in standard construction processes.

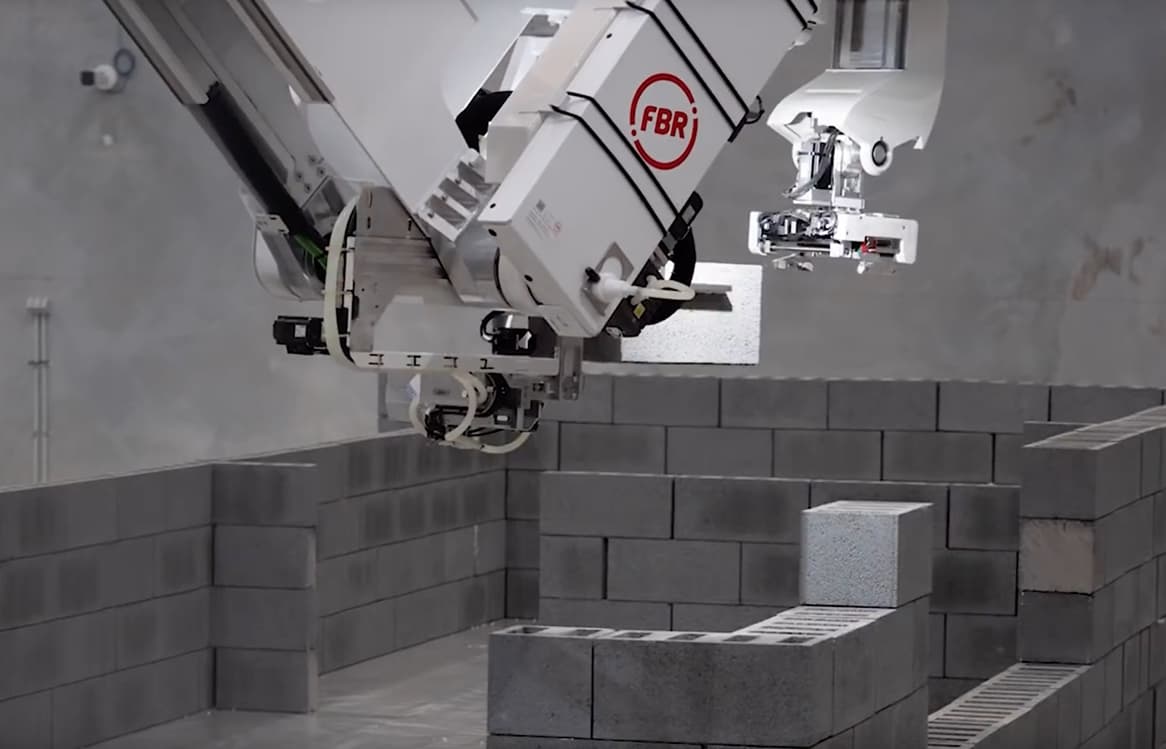

HADRIAN X is a robot developed by Australian company FBR, earlier known as Fast Brick Robotics. This robotic technology company achieved a technical milestone in 2015 by successfully demonstrating its first robotic home-building technology by constructing a 180m2, 3-bedroom, 2-bathroom home structure in less than the three-day target. Structural and civil engineers independently confirmed that the structure complied with the relevant building codes.

FBR CEO Mike Pivac expresses: “We are all justifiably proud and excited to have achieved this world-first milestone for FBR. We now have the world’s only fully automated, end-to-end bricklaying solution, with a massive market waiting for it. We now begin the next exciting phase for the Company as we execute our global commercialization strategy to capitalize on the significant demand for our technology."

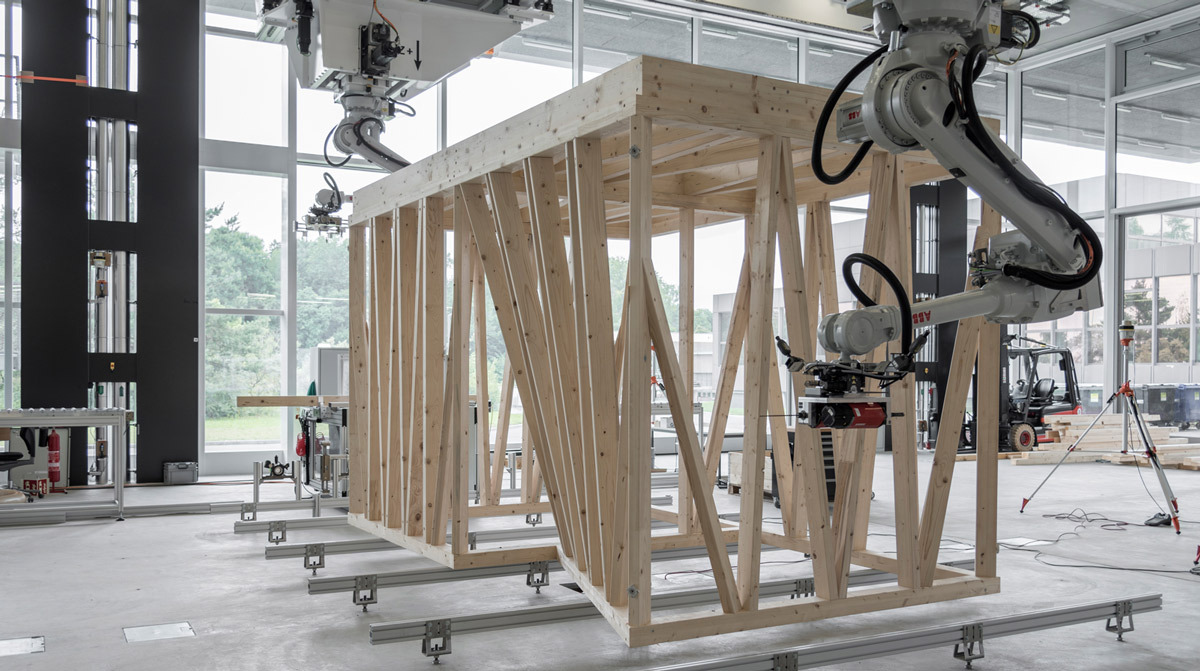

DFAB HOUSE A three-story residential unit that is part of Empa and Eawag’s NEST research and innovation platform in Dübendorf, Switzerland. Designed and Printed at the Robotic Fabrication Laboratory at ETH in Zurich. A perfect example of robotic collaboration in timber construction.

LA-SPHERE a freestanding guardhouse printed with mobile 3D printer called CyBe RC (Robot Crawler). Easy to be transported to any location for print with high-quality strength, range, and adhesion. It is considered one of the most efficient concrete printers in the world.

On-site Automation: Automation in on-site construction, however, offers distinct potential as well as obstacles. It takes new tools and procedures to develop and implement equipment, which reduces the direct transfer. Some of the earliest examples of on-site automation led to building systems that were specifically designed to integrate with automated construction methods, which reduced the uniqueness of the building.

Today, automated construction supports variations across units while also using standardized elements. A prime example is automated equipment that places concrete reinforcement, eliminates repetitive tasks on the job site, allows performance-driven variability in rebar placement without incurring extra cost, and, by placing material precisely where it is needed, reduces waste. For instance, a construction company in Japan used automated rebar placement to build a complex bridge, reducing both construction time and material waste by over 30%.

KAMP C The award-winning office space Kamp C, located in T Centrum in Belgium, is Europe’s first 3D-printed two-story house. The whole construction was 3D printed directly on-site, with 8m tall walls and 90 m2 indoor floor area.

BUCKMINSTER FULLER VISITOR CENTRE: A visitor center and museum located in Carbondale, USA. Designed by architect Buckminster Fuller as an innovative and sustainable practice. The center includes custom parametric 3D-printed components.

In the modern era of construction, minimum human efforts are supposed to be needed. It is presumed that advanced manufacturing and automation will replace human labor in the near future. One must schedule weekly or daily scans once at the start of the project and "leave and forget." When the time is set, the robots start up on their own, find their way to destinations, climb floors, and park to recharge.

There will be a platform to distribute the task between all the robots deployed at a particular construction job site based on each robot’s location, battery level, stairs and hoists availability, designated no-go zones, known obstacles, and charging station locations.

It’s like what Warren Bennis, an American scholar and pioneer in leadership studies, famously wrote: “The factory of the future will have only two employees, a man and a dog. The man will be there to feed the dog. The dog will be there to keep the man from touching the equipment.”

However, in reality, many believe close collaboration between humans and automated systems is required. The future of construction is not a battle but a partnership. Imagine robots tackling tedious and perilous tasks, freeing skilled humans to unleash their creativity. Together, machines and minds will revolutionize how we build, letting ingenuity and problem-solving take center stage. In this harmonious collaboration, progress becomes a shared endeavor.

Automation is quickly expanding technology; construction stakeholders have the ability to enhance their workflows by combining advanced automation and creativity. PAACADEMY’s Parametric Workflows with Blender workshop and course teaches how to create custom toolpaths for 3D printing, CNC, and robotic fabrication using Blender's Geometry Nodes.

The trend towards increasing prefabrication suggests that over time, many tasks currently performed on-site will be largely moved off-site. We expect this to skew the landscape of on-site construction tasks away from lower-order tasks that deal with raw materials and towards the assembly of higher-order building modules. Finally, to prepare employees for an increasingly automated future, we need innovative training. As technology advances, the dream of fully automated construction sites shifts closer to reality. This shift promises to revolutionize the way we build and manage infrastructure across the globe.

You must be logged in to comment.