Studies show that from the beginning of 20th century the carbon footprint of the people has increased every year. The pollution caused by wastes is effecting our present time but also the future. At this point sustainability has became an obligation rather than a option. For all that sustainability concept has shed light to the new technological improvements and made it increasingly widespread.

One of the most important improvement is the 3D printing technology, which has gradually developed and has reached a point where it provides over %90 environmental efficiency. This new technology has a great potential with its sustainable raw materials, that can grow everyday as a material, as well as contributions such as saving labor time, time and energy.

It is a layered manufacturing technique that can be transformed from a virtual world that it has created into a solid model. 3d printing has many advantages when comparing to the other manufacturing processes as it can create new products very quickly and precisely. In 3D printing, most materials used are plastics and polymers. Ceramics can also be used, and products can be made from recycled or organic materials, reducing environmental impact. These materials are versatile and can be formulate to meet the need of the esthetic requirements.

3D printing creates new opportunities in interior design, the development of this technology has expanded the range of materials which initially consisted mainly of polymers, different materials such as sand, wood marble and ceramic clay can now be used. Since interior design is a discipline that contains creativity, 3D printing is a logical choice that opens a point of view.

There are many different printing processes, and the type should be considered with number of factors such as the desired surface, compatible material or desired finish.

One of the techniques that is used is SLS (selective laser sintering); This technology creates designed objects layer by layer by melting them with a laser, it is suitable for complex and detailed designs for instance; the famous Swedish brand IKEA adopt the 3D printing in their design with the collection that collaborated with Bea Akerlund with SLS printing technology.

Binder Jetting; this technology allows many different materials to be combined with binders to be built layer by layer. A wide variety of materials such as wood, metal, ceramics can be used with this technique.

FDM technology; allows thermoplastic materials to be fused together layer by layer, in this technic materials mostly used are thermoplastics such as PLA, ABS, nylon or PETG therefore it can be also used for homeowners because of its cheap materials. there is also technologies called SLA (stereolithography), DLM (digital light processing) MJF (multi jet fusion) Polyjet, LOM (laminated object manufacturing) DMLS (direct metal laser sintering) CLIP (Continuous Liquid Interface Production), Material jetting, DOD (drop on demand), Bio printing.

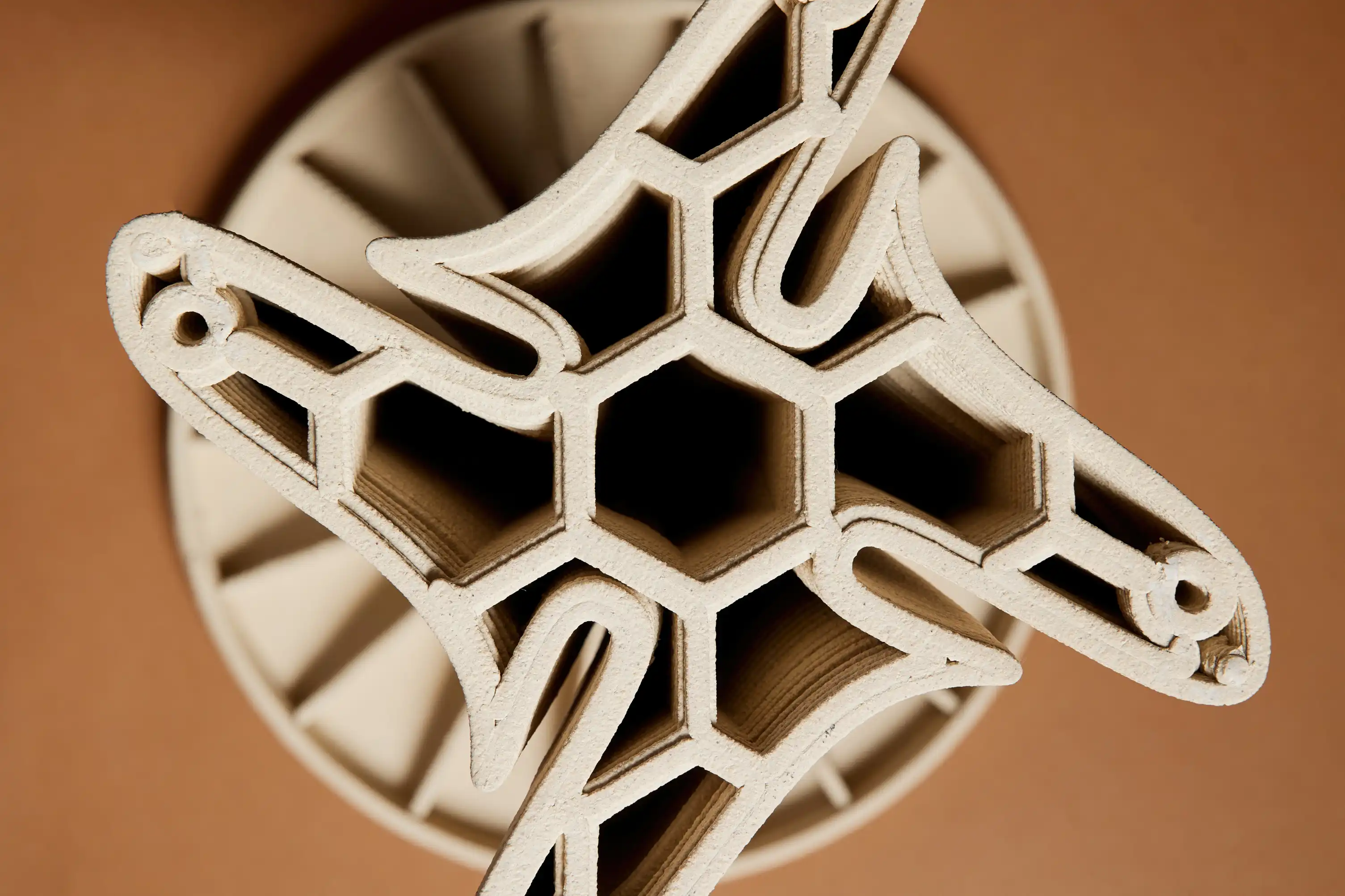

Another one is LDM ( liquid deposition Modeling) which effects the ceramic 3D printing especially, this technic is useful for ceramic material; it allows interaction during the process and make it possible to do printing in medium/large scale, it is fast with using all ceramic materials.

Greek studio Keramik is using this technic for their collections which are diverse products such as tables, furniture, lighting and decorative objects, with merging the traditional and technology.

The interior design is actually sits on the center of our lives, it is a discipline that creates the experiment of a space, this practice happens with the formulation of the mass and the surfaces. Interior design is at every point in our living such as; bathrooms, kitchens, living rooms, bedrooms and also in the consumer areas.

3D printing is becoming a part of this interior design discipline as we can see in our living spaces, because the variety coming from the 3D printing assist to personalize your house and design your wants, this is why it also concerns not just the designers but also the homeowner, the adjustment of 3D printing to our everyday life creates advantages for the homeowners because of its personalization. Decorating a house is a very personal thing and hiring a interior designer choice may change due to the budget, this technology gives opportunity to homeowners to create, change and personalize their environment.

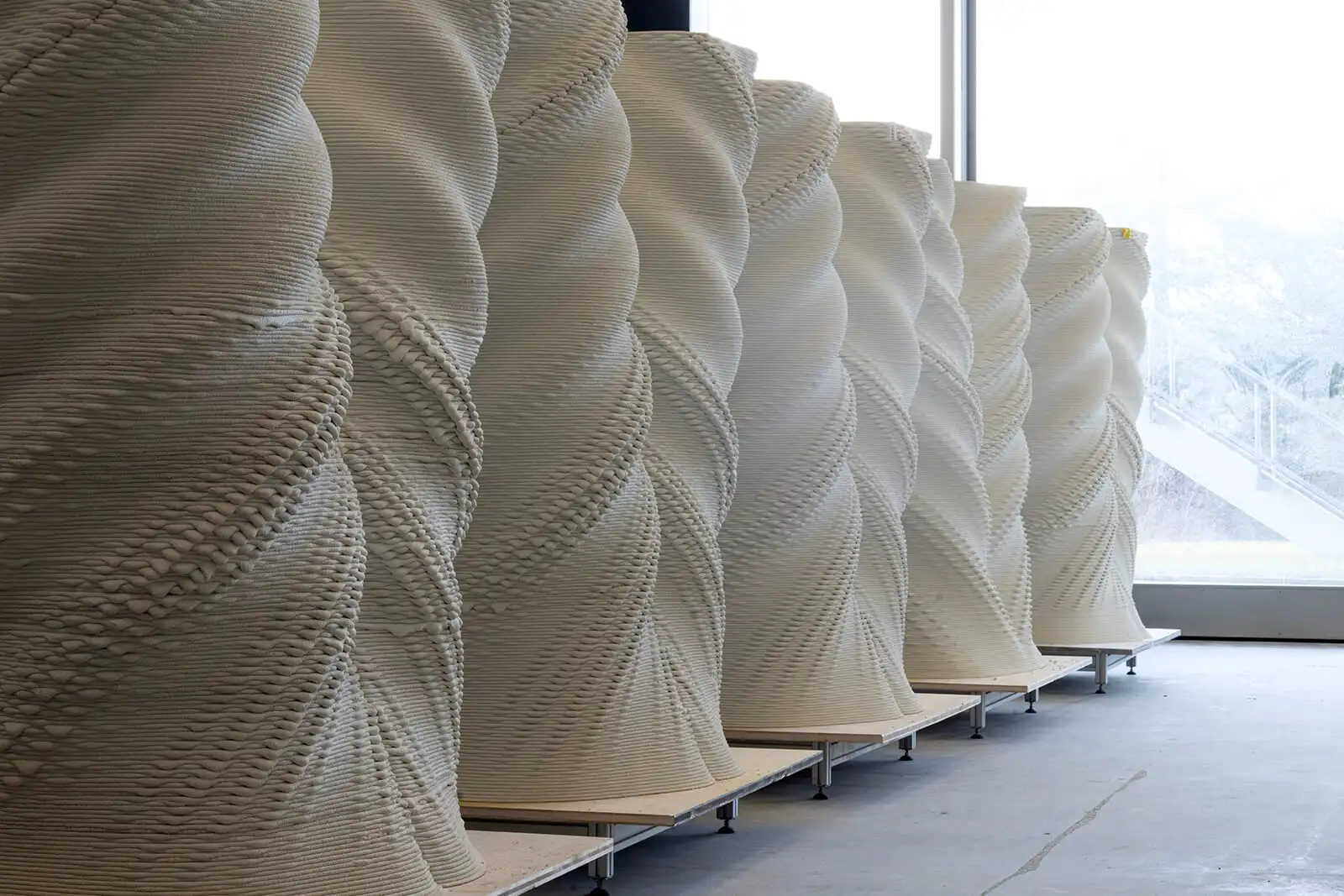

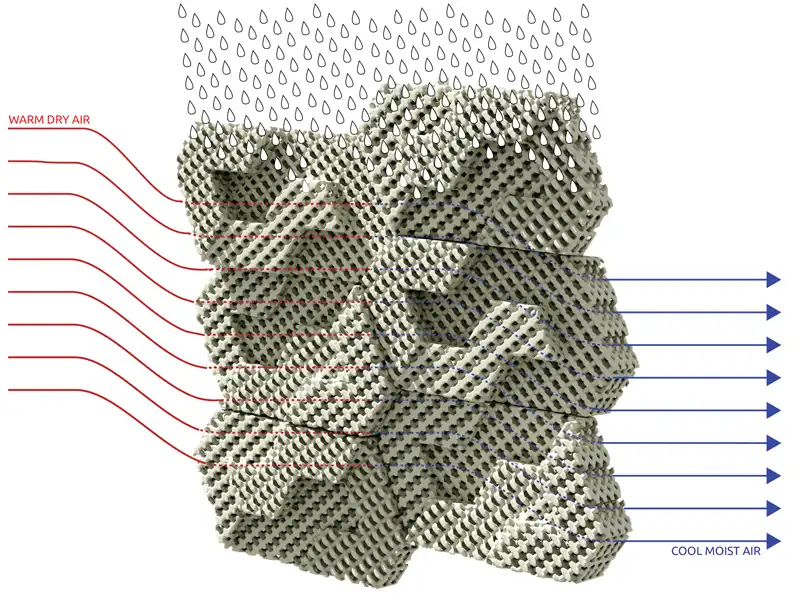

If we consider professional part there are many innovative and encouraging articles for designers to add more 3D printing designs for the sustainability. The usage of 3D printing has also increased between design offices, for all that it creates an inspiring aspect in the field of design. For instance, Emerging Objects; a design office that creates 3D ceramic objects in many areas and scales, one of the designs is the ’cool brick’ which inspires from the past with its sustainability, this objects meet the need of passively cool interiors in desert environments, in their vision ‘It takes an average of 39 years for a new technology to become normalized.

3D printing ceramics was invented in 2010, so by this measure, we will see 3D-printed ceramic objects, interiors, and buildings as commonplace by 2049.’ (Emerging Objects, 2024) This gives a positive point of view to see the sustainable movement of this area to became more spread around the world, this studio also provides consultation for the other companies to raise awareness about the sustainable effect and how to use it into their need.

Another example comes from a architecture studio in Rotterdam, the Studio RAP it creates a harmonious architecture that inspires from traditional and modern, the office designed the facade according to the street in a sustainable solution. The facade formed with 40x20 scaled pearl white and yellow touched 3D printed ceramic tiles, at the upper levels the material is 3D printed bricks polished with three different shade of red. Therefore they made a sustainable design that suits the traditional architecture and this solution shows, sustainable environments and 3D printing may adjust to various parts in design and architecture but also in time.

.webp)

.webp)

The growing trend in 3D printing emphasizes the use of bio-based and recycled materials, with more design offices embracing these technologies and exploring creative applications. Consultancy services play a key role in raising awareness and sharing knowledge across firms. As designers shape spaces and, in turn, the environment, sustainability becomes an integral part of the design process. This evolution paves the way for wider adoption of these technologies across both decorative and functional scales in the future.

As 3D printing continues to revolutionize design and sustainability, there's never been a better time to explore its potential. Whether you're interested in 3D-Printing Ceramics, or FDM innovations, PAACADEMY offers in-depth workshops covering these techniques. For a comprehensive learning experience, check out the 3D Printing Workshop Bundle—a curated collection of courses designed to take your skills from concept to fabrication.

You must be logged in to comment.