Additive manufacturing, another name for 3D printing, is a new-age digital fabrication technique that builds tangible products from virtual 3D models by layering on material. In contrast to conventional subtractive techniques, which involve carving or cutting away material, 3D printing creates an object from the ground up, providing unparalleled precision, efficiency, and design freedom. A digital model, usually produced using CAD (Computer-Aided Design) software, is the starting point of the procedure. It is then sliced into layers that direct the printer's movements. The final product is created by layer-by-layer deposition or fusion of materials such as plastic filament, resin, metal powder, clay, or even concrete, depending on the method employed.

Rapid prototyping, mass customisation, and the creation of extremely complex geometries that would be challenging or even impossible to manufacture with conventional equipment can now be done by this technology. It has affected everything from architecture and product design to fashion, medicine, and aerospace. For instance, 3D printing is being used in architecture to print modular structures, build whole buildings, and experiment with sustainable design using materials like earth or recycled plastic.

3D printing is more than just a tool; it's a paradigm shift in how we design and manufacture in the twenty-first century because of its capacity to cut down on material waste, speed up production, and open up new avenues for creative expression. Let’s explore some of the workshops that PAAcademy has to offer on 3D-printing technology, hosted by versatile architects and designers from all over the globe.

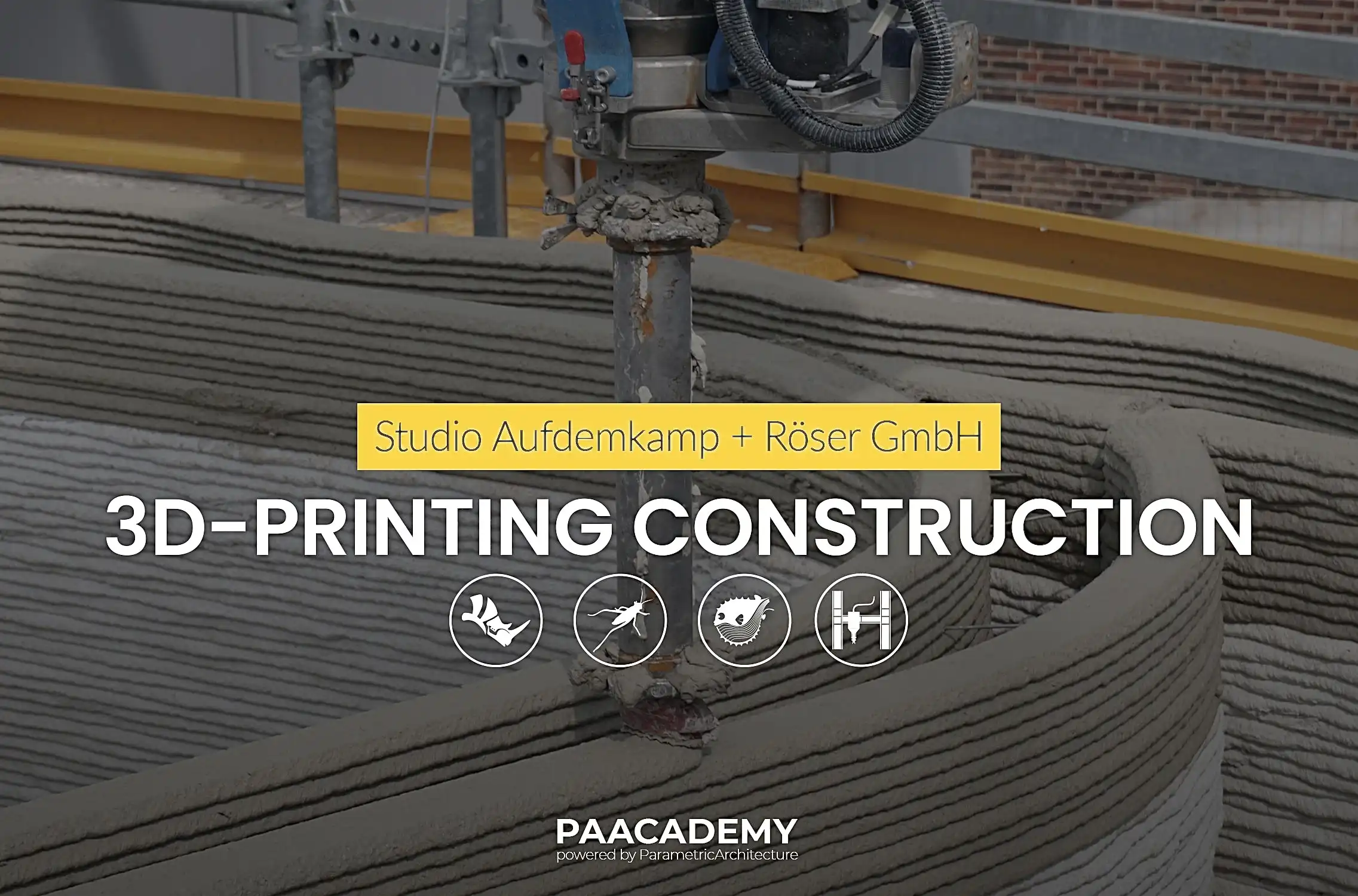

He focuses on designing and producing 3D-printed structures. Through partnerships with companies such as Roeser GmbH and PERI 3D Construction, he has gained proficiency in parametric workflows, BIM-based planning, and digital fabrication. He employs AR/VR tools and custom Grasshopper scripts to streamline the 3D printing process.

With an emphasis on how new technologies are changing the design and construction process, the 3D-Printing Construction workshop examines the real-world applications of additive manufacturing and 3D printing in architecture. Participants will gain knowledge about how to create complex geometries for building, such as organic walls, curved facades, and freeform floor plans, using parametric design tools. With a combination of theoretical lectures and software-based activities that walk participants through each step of the workflow, the workshop is intended to be interactive.

The main focus of the session is parametric modeling with programs like Grasshopper, Rhino, and plugins like Pufferfish. Three parts make up the workshop's structure: a lecture that covers important topics, a software exercise that uses Grasshopper and Rhino to put those concepts into practice, and a live printing session that shows how digital models are turned into tangible objects. A shared Discord server facilitates peer review and collaborative debate while each member works on a separate project. By the end of the course, participants will have the knowledge and attitude necessary to optimize their designs for 3D printing and comprehend the opportunities it presents in the larger framework of architectural innovation.

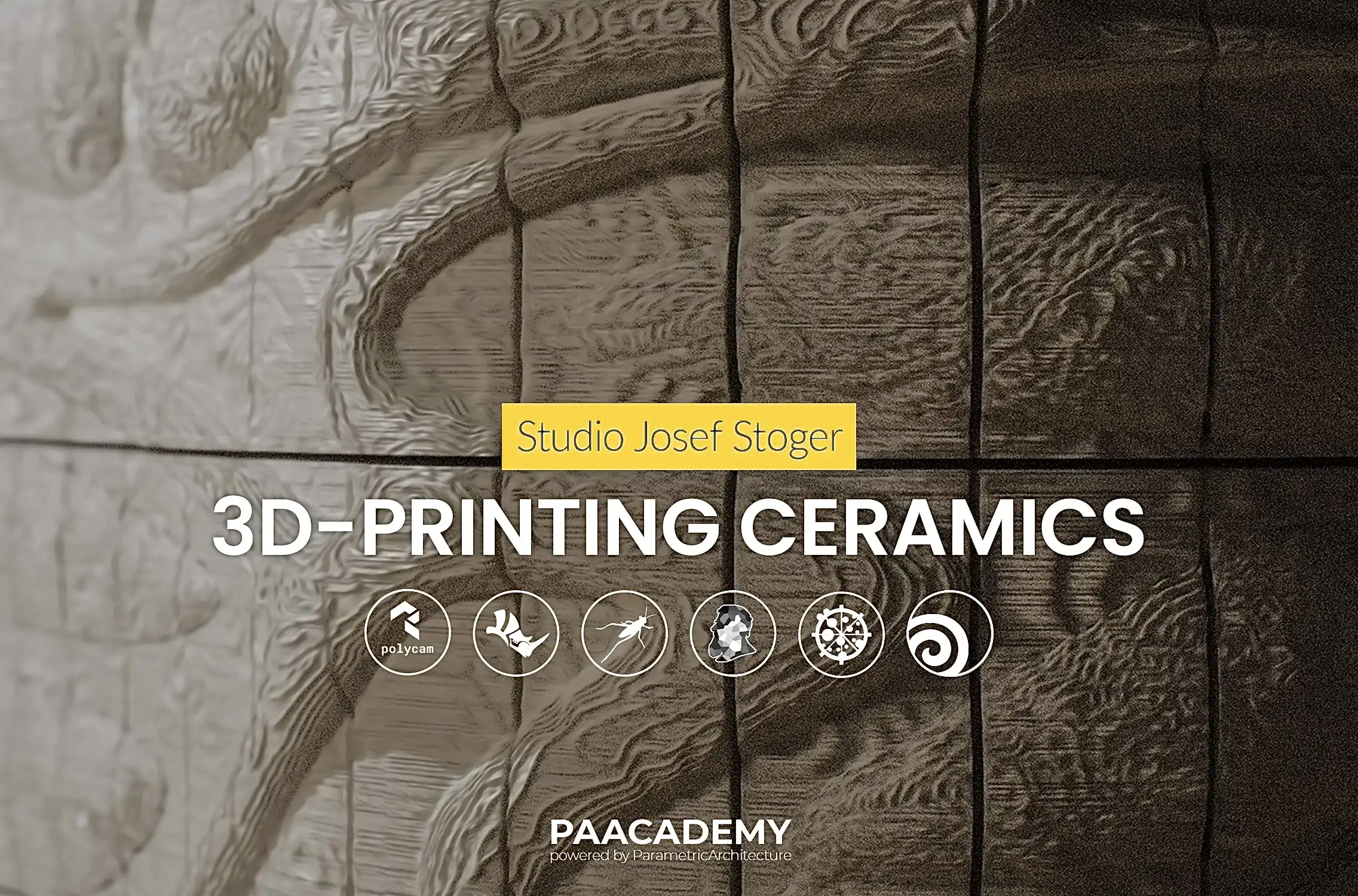

Josef Stöger is a designer and artist whose work includes digital fabrication, virtual reality, and filmmaking, and is inspired by natural systems. He now concentrates on commissioned artworks and teaching digital and physical design. He formerly worked as a technical tutor at the Bartlett and has recently collaborated on projects including a 3D-printed ceramic sculpture for Peugeot.

The 3D-Printing Ceramics workshop examines how digital design and clay-based 3D printing can be combined, with a focus on workflows across various software platforms. Under the direction of Josef Stöger, the workshop exposes participants to a hybrid methodology including traditional craftsmanship, robotic fabrication, and computational technologies.

In order to generate contextual data from real-world situations, the method starts with photogrammetry using Polycam. After that, base geometries are created in Rhino and converted into tool paths in Grasshopper, providing form and fabrication logic control. Houdini is used as a step in between to add more complexity, and tool paths are then polished and exported as Gcode, which can be tailored for industrial robotic arms, PLA machines, or clay printers.

The program stresses software hopping as a crucial methodology, instead of concentrating on a single platform. In addition to manipulating fabrication data and comprehending the material behavior of clay, participants will learn how to include environmental context into digital models. Focusing on post-processing and the value of human interaction in enhancing printed artifacts, the workflow comes to a close.

This session is intended to provide an overview of a thorough digital process and not a step-by-step lesson. From object design to architectural applications, it exposes participants to a variety of tools and techniques that can be tailored to different scales.

She is an expert in 3D printing who has experience in digital fabrication, computational design, and architecture. She is based in Germany and specializes in affordable housing. She received recognition for her work on the Beyond Shelter project in ICON Technologies' Initiative99 competition. Additionally, she experiments in 3D-Printing Innovations.

Participants in this course will learn the basics and more complex methods of Fused Deposition Modeling (FDM) 3D printing with Rhino, Grasshopper, and Cura. Under the direction of Victoria Roznowski, the workshop focuses on creating useful design processes for tiny interior objects and looks at how to leverage custom scripting and slicing to provide fine-grained control over the printing process.

First, participants study the fundamentals of 3D printing technology, including printer hardware, slicing techniques, and material types. The workshop then switches to a parametric design methodology, creating custom toolpaths and G-codes in Grasshopper and creating geometries in Rhino. The approach stresses direct manipulation of manufacturing parameters to enable design freedom and performance adjustment.

A combination of lectures, software tutorials, and practical exercises make up the technique, which ends with live printing sessions. In order to save production time, designs are scaled down to about 10 cm, yet this allows for the investigation of more experimental shapes and materials. Additional production methods, including printing on fabric substrates, and flexible materials, such TPU, are introduced in later sessions.

Participants with printing capabilities are invited to experiment in real-time, but they are not necessary to have access to a personal 3D printer. Functional prototypes and exploratory design artifacts are among the results of the workshop, which offers an organized yet flexible framework for learning and testing FDM-based workflows.

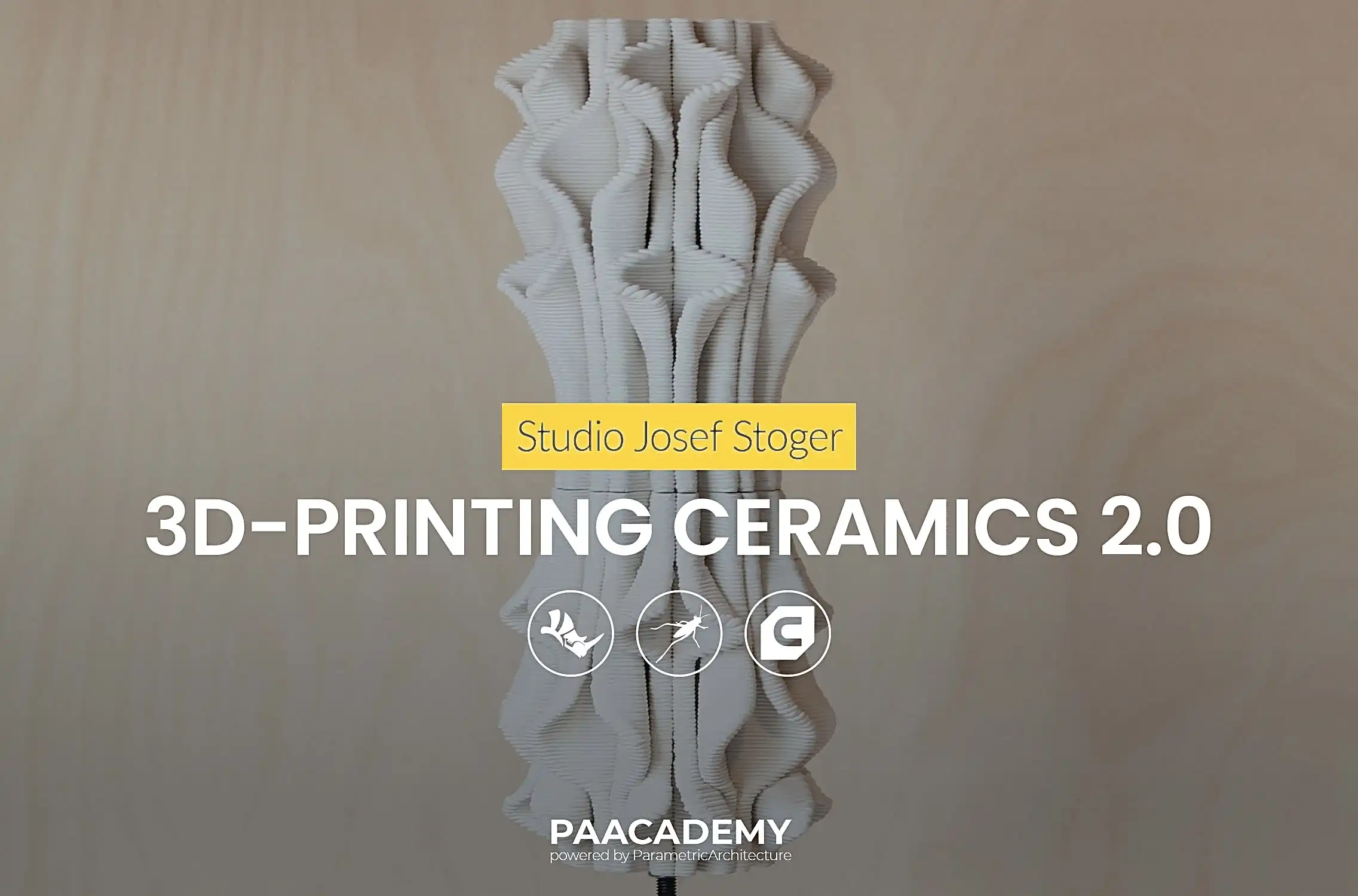

With an emphasis on the technical and artistic facets of clay 3D printing, the 3D-Printing Ceramics 2.0 workshop provides a number of supervised activities to foster the development of useful abilities in digital setup, fabrication control, and material comprehension. Under the direction of Josef Stöger, the workshop expands on the foundational ideas of additive manufacturing and uses parametric modeling and bespoke toolpath generation to apply them to ceramic workflows.

The course is organized around ten practical exercises that gradually cover every step of the workflow, from creating bespoke G-code and print paths in Grasshopper to preparing files in Cura. With a focus on honing clay print techniques including layer-specific choreography, variable extrusion, and non-planar printing, participants gain a thorough understanding of how digital design influences tangible results.

Selected participant files are printed in real time during the session, facilitating discussion and assessment in real time. This element facilitates group learning from both successful and unsuccessful prints, creating a feedback loop between material performance and digital intention. Additionally included are post-processing methods, emphasizing how clay prints can be improved after production.

To participate, you do not need to have access to a clay 3D printer. The emphasis is still on creating processes that can be applied to various clay printers, ranging from do-it-yourself setups to large-scale devices. The training covers various printer parameters and material concerns pertinent to ceramic printing in addition to software expertise.

Kristýna Uhrová is an architect focused on experimental design and digital fabrication. She works with Subdigital, contributing to the development of Monoceros, a Grasshopper plugin using Wave Function Collapse for spatial pattern generation.

Jiří Uran Vítek is a digital architecture researcher and educator at Brno University of Technology. A graduate of Brno and Die Angewandte Vienna, he leads Research Cluster URAN and is Creative Director at Chybik Kristof Architects.

Michal Mačuda is an architect specializing in 3D concrete printing and infill design. He works at ICE Industrial Services and is a graduate of Brno University of Technology.

This workshop bridges the gap between digital modeling and full-scale physical output by introducing participants to the process of developing architectural components specifically for 3D-Printing Concrete. Participants will learn how to construct structurally aware geometries that are optimized for real-world production using programs like Rhino 7, Grasshopper, and related plugins.

The class focuses on designing and developing a facade element, taking a look at the complete process from conceptual sketch to materialization. An introduction to 3D printing in architecture, its technological development, and the unique design issues that set it apart from traditional construction techniques are covered in the first theoretical portion of the course.

After that, participants will use parametric tools to shape their designs through guided exercises. Using plugins like Ladybug, Karamba3D, Pufferfish, and Monoceros for performance evaluation and shape refining, the course stresses not only form production but also factors like structural behavior and printing limitations.

Preparing data for 3D concrete printing is the aim. Each participant will create a printable section of a load-bearing facade as a practical result. Furthermore, one or two chosen student drawings will be printed at full size, providing immediate feedback on the conversion from digital to physical.

This class emphasizes the growing importance of the 3DCP Architect (3D Concrete Printing Architect), a design expert who is proficient in digital production methods, fabrication logic, and material behavior in addition to architectural form.

Alejandra Rojas is an artist, designer, and educator from New York who focuses on ceramic fabrication and computational design. She combines architectural techniques with sculptural clay work. Her work has been shown all over the world, from Paris Art Week to Milan Design Week, and her studio practice focuses on pattern and shape.

Participants in this 3D-Printing Clay workshop will learn how to use clay 3D printing technologies to create parametric ceramic forms. Led by Alejandra Rojas, the workshop examines the relationship between computational design and traditional ceramics, emphasizing the use of digital toolpaths and patterns to create tactile, expressive clay geometries.

Participants will create and improve geometry and G-code using Rhinoceros, Grasshopper, and slicing tools like Cura and PrusaSlicer. Gaining control over the printer's movement routes is a key goal of the workshop since it enables the creation of non-planar structures, structural patterns, and layered, personalized surface textures.

The course is divided into four progressive workflows, starting with basic modeling and slicing and working up to advanced G-code creation directly from Grasshopper. The main goal of each workflow is to create vertically oriented typologies, including towers and columns, that show off clay's versatility as a medium for both design and production.

Hands-on exercises and demonstration films enhance the learning process, with each phase designed to balance technical skill-building and artistic experimentation. Participants will get a more profound comprehension of the physical characteristics of clay throughout, including print preparation, material behavior during printing, and post-processing phases.

Although printing examples are given, access to a clay printer is not necessary for this session. It seeks to equip participants with the abilities and know-how to create unique ceramic components.

Participants in the 3D-Printed Wall Panels class learn how to use desktop 3D printers to design and fabricate personalized wall panel systems. The program, which is led by Victoria Roznowski, focuses on parametric modeling, modularity, and workflows that are ready for manufacture while examining the aesthetic and practical aspects of wall panel design.

Using Rhinoceros, Grasshopper, and Cura, participants will create a nine-part modular wall panel system. Following an overview of fundamental design concepts including connection details, pattern generation, and assembly logic, the program transitions into practical exercises where participants use parametric design techniques to produce unique toolpaths and G-code.

In order to help participants understand how design choices scale across various materials and processes, the course covers techniques appropriate for both small-scale PLA printing and large-format fabrication, including concrete printing.

Participants will learn how to create and export print files that are optimized for 0.4mm and 0.8mm nozzle diameters, as well as how to adjust slicing software parameters for form clarity and material efficiency. Foundational principles are introduced early in the program to ensure all participants are prepared for increasingly complex activities, but no prior expertise is necessary.

Participants will have finished a 3D-printed wall panel prototype by the end of the workshop, gaining knowledge about digital-to-physical processes and the function of parametric tools in the design of architectural components

The way architects and designers conceptualize, prototype, and construct is changing as a result of the development of 3D printing as a potent design and production technology. Participants in these seven classes on PAAcademy can learn about the wide range of additive manufacturing applications, from sophisticated FDM processes to clay and concrete. In addition to developing technical skills, each course promotes material awareness, creative experimentation, and an awareness of workflows from digital to physical. These seminars provide a practical introduction to the future of design and manufacturing, regardless of your background as a student, practitioner, or educator.

You must be logged in to comment.